FFKM O-RINGS | MATERIALS SIMPLY EXPLAINED

What are FFKM O-rings?

FFKM is currently by far the best performing O-ring material.

In contrast to all other O-ring materials, FFKM O-rings can withstand temperatures of up to +340°C. In addition, every perfluoro rubber compound is resistant to almost all chemicals. At present, the combination of these two properties is unique.

Furthermore, FFKM O-rings are even fully elastic. They can therefore be used as flange, piston or rod seals without any problems.

Feature | Value |

|---|---|

ISO designation | FFKM |

Chemical name | Perfluoro rubber |

Media resistance | Almost universally resistant to media |

Temperature resistance | -40°C to +340°C (depending on mixture) |

Standard color | Black |

Standard hardness | 75 Shore A |

Scope | Chemicals, food, pharmaceuticals, oil & gas |

Production | Compression molding and injection molding |

Tolerances | DIN ISO 3601 |

Durability | 13 years |

Biggest disadvantage | High price |

Differences in commodity prices

Material | NBR | EPDM | VMQ | HNBR | FKM | PTFE | FEP | FFKM |

|---|---|---|---|---|---|---|---|---|

Factor | 1 | 1,5 | 1,9 | 2,7 | 3,9 | 24 | 51 | 329 |

Correct interpretation: NBR is the cheapest material compared to the other O-ring materials. The factor indicates how much more expensive a material is compared to NBR.

Example: FKM is 3.9 times more expensive than NBR. FFKM is 329x more expensive than NBR.

REQUEST FFKM O-RINGS QUICKLY AND EASILY?

Almost any dimension available

Over 10,000 FFKM dimensions available from stock

Offer received in record time

ECOLAST®: FFKM O-rings in European brand quality

#1 FFKM (perfluoro rubber)

Perfluoro rubber (FFKM), also known as perfluoroelastomer, is a special material that is primarily used as a sealing material.

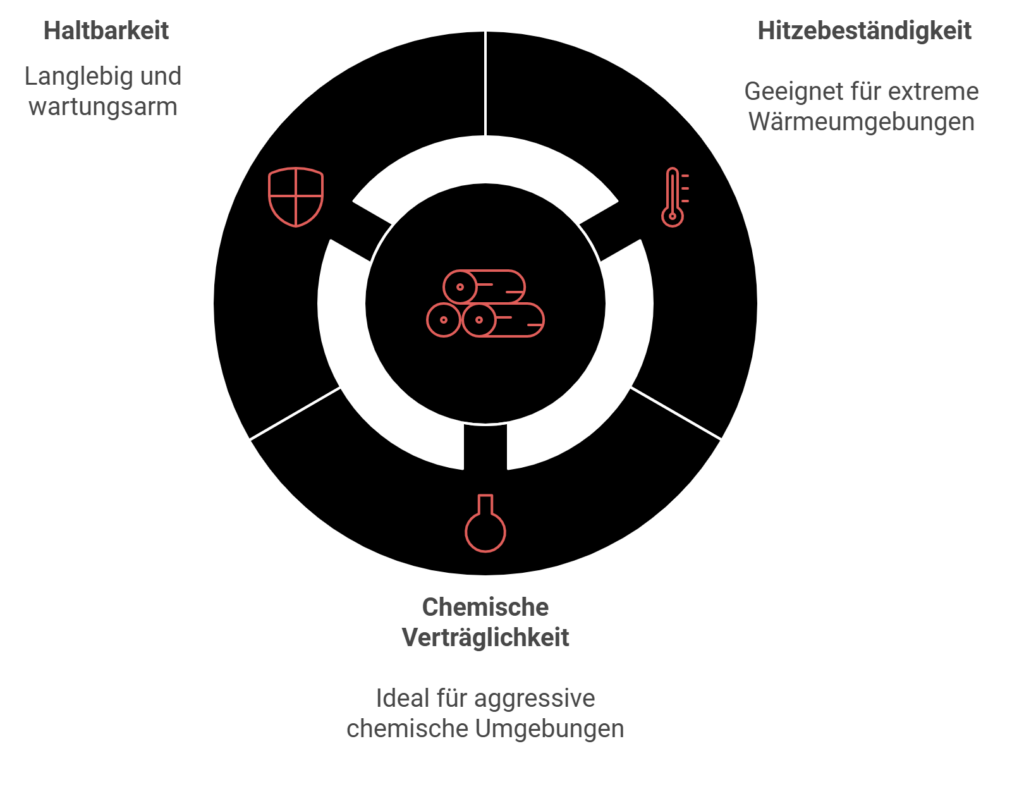

The special features of FFKM lie in its exceptional properties, which distinguish it from other materials:

High fluorine concentration: FFKM contains a higher amount of fluorine than standard FKM (fluororubber), which gives it improved properties. This higher fluorine concentration results in better resistance to high temperatures (up to approx. 325°C) and almost universal chemical compatibility. These properties make FFKM particularly suitable for use in environments with very aggressive media.

Resistance to extremely high temperatures and chemicals: One of the most striking features of FFKM is its ability to withstand extreme temperatures and a wide range of chemicals. This resistance makes it an ideal material for demanding applications, especially in the chemical and pharmaceutical industries, where it is used for O-rings, rotationally symmetrical molded parts and seals.

High durability and long service life: Despite the high costs, the outstanding properties of FFKM, such as its durability and long service life, offer low-maintenance and sustainably profitable use, especially in high-tech applications.

However, the production of FFKM is associated with high costs. This is mainly due to the technically complex manufacturing process.

The production of perfluoro rubber is complex and requires special processes and materials that drive up the price.

These high production costs mean that FFKM is not a mass-produced plastic and its use is limited to special applications where its unique properties are indispensable

#2 FFKM O-rings: The king of elastomers

It is important to know that elastomer materials such as NBR, FKM or FFKM are dimensionally stable plastics. This allows them to deform elastically under tensile or compressive load and then return to their original shape.

Particularly in applications with high requirements, conventional O-ring materials such as NBR, EPDM or FKM are often no longer sufficient. For temperatures above +200°C and aggressive chemicals, only special materials such as perfluoroelastomers can be used.

What are the 5 most important advantages of FFKM O-rings?

1. almost universal media resistance

2. temperature resistance of up to +340°C

3. Elastic

4. Available in a variety of compounds

5. Excellent compression set (durability)

The starting point for the correct selection of an O-ring material is always the requirements of the application. To make it easy for you, we have put together a table with the properties of the most important O-ring materials.

Material | Temperature resistance | Chemical resistance | Elasticity |

|---|---|---|---|

NBR | -30°C to +120°C | Low | High |

HNBR | -30°C to +150°C | Medium | High |

EPDM | -45°C to +150°C | Medium | High |

SILICONE | -60°C to +200°C | Low | High |

FKM (VITON) | -25°C to +200°C | Medium | High |

FEP coated | -60°C to +200°C | High | Medium |

PTFE | -250°C to +250°C | High | Low |

FFKM | -40°C to +340°C | High | High |

In summary, FFKM is far superior to all other O-ring materials. However, there is also a catch.

This is because O-rings made of FFKM are very expensive compared to other materials. They should therefore only be used where no other O-ring material would work.

It is therefore not surprising that O-rings made of perfluoro rubber are mainly used in sensitive industries such as the chemical and pharmaceutical industries.

Basically, every industry has its own requirements and demands on the FFKM material.

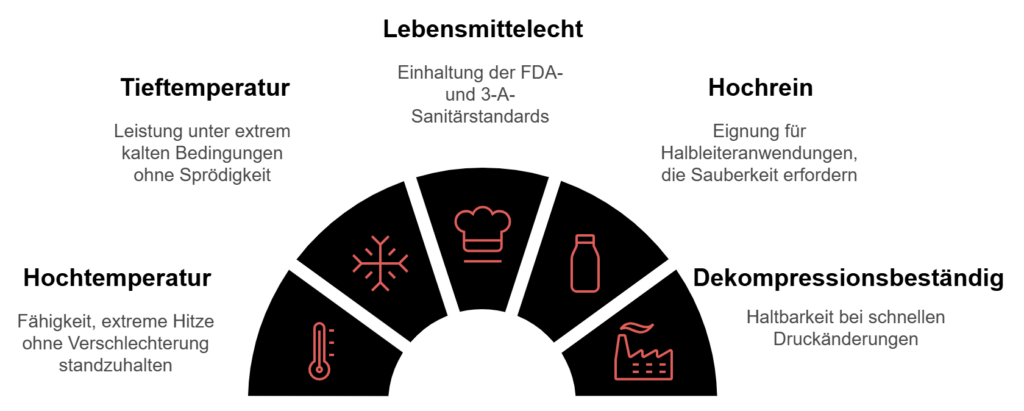

What are the requirements for FFKM O-rings?

1. High temperature

2.Low temperature

3. Food-safe (FDA and 3-A Sanitary approvals)

4. high purity (semiconductor applications)

5. Decompression resistant (NOROSK M710)

In order to cover a wide range of applications, FFKM is available in a large variety of compounds. The different composition of the material can be used to adjust the temperature range, elasticity or hardness, for example.

Summary Chapter 1: FFKM basic knowledge

FFKM O-rings are clearly superior to all other O-ring materials in terms of thermal and chemical resistance. In addition, FFKM is produced in a variety of material mixtures.

#3 Pure variety: Overview of all FFKM O-ring compounds

We have compiled tables to give you a quick overview of all FFKM mixtures. The tables are divided into the 4 main application areas.

What are the 4 main areas of application for FFKM O-rings?

1. chemical industry

2. food and pharmaceutical industry

3. oil and gas industry

4. semiconductor industry

Important note: As a reference for the various mixtures, we have used our own FFKM brand “ECOLAST®” as a reference.

FFKM mixtures: Chemical industry

Ecolast | Color | Temperature | Hardness | Applications | Data sheet |

|---|---|---|---|---|---|

NH5600 | Black | -25°C to +270°C | 60 Shore | All-rounder | |

NH5750 | Black | -25°C to +270°C | 75 Shore | All-rounder | |

NH5751 HT | Black | -15°C to +330°C | 75 Shore | High temperature | |

NH5755 HT | Black | -15°C to +330°C | 75 Shore | High temperature | |

NH5756 HT | Black | -15°C to +340°C | 75 Shore | Hot water, steam | |

NH5760 LT | Black | -40°C to +250°C | 75 Shore | Low temperature | |

NH5900 | Black | -20°C to +270°C | 90 Shore | All-rounder |

FFKM mixtures: Food and pharmaceutical industry

Ecolast | Color | Temperature | Hardness | Applications | Data sheet |

|---|---|---|---|---|---|

NH4600 | White | -20°C to +270°C | 60 Shore | All-rounder: FDA, USP Class VI, 3-A Sanitary | |

NH4700 | White | -20°C to +270°C | 70 Shore | All-rounder: FDA, USP Class VI, 3-A Sanitary | |

NH5700 | Black | -25°C to +270°C | 70 Shore | All-rounder: FDA, USP Class VI, 3-A Sanitary | |

NH4701 HT | White | -15°C to +300°C | 70 Shore | High temperature: FDA, USP Class VI, 3-A Sanitary | |

NH4702 LT | White | -40°C to +250°C | 70 Shore | Low temperature: FDA, USP Class VI, 3-A Sanitary | |

NH4750 HT | White | -15°C to +315°C | 75 Shore | High temperature: FDA, USP Class VI, 3-A Sanitary | |

NH4800 | White | -20°C to +270°C | 80 Shore | All-rounder: FDA, USP Class VI, 3-A Sanitary | |

NH4801 HT | White | -15°C to +300°C | 80 Shore | All-rounder: FDA, USP Class VI, 3-A Sanitary |

FFKM mixtures: Oil and gas industry

FFKM compounds: Semiconductor industry

Ecolast | Color | Temperature | Hardness | Applications | Data sheet |

|---|---|---|---|---|---|

NH7100 | White | -20°C to +300°C | 75 Shore | High purity, plasma resistant |

So you can see how many different requirements are placed on FFKM O-rings. Accordingly, there are many compounds.

At this point, we will take a very brief look at the requirements and special features of the four application areas.

1. chemical industry

Requirement: Aggressive media meet high temperatures

Solution: Mixtures with high chemical and thermal resistance

2. food industry

Requirement: High purity requirements and cleaning with aggressive chemicals

Solution: Mixtures with high chemical resistance and FDA approval (food)

3. oil and gas industry

Requirement: High pressure in combination with high temperatures

Solution: Compounds with 90 Shore and against decompression resistant

4. semiconductor industry

Requirement: Extremely high purity requirements and plasma as a medium

Solution: Mixtures that are highly pure (do not release any substances) and are plasma-resistant

We know from experience that the variety of perfluoro rubber compounds can be overwhelming. We hope that the tables have given you a rough overview.

If you have any questions about selecting the right mixture for your application, you are of course welcome to contact us for advice at any time.

Summary Chapter 2: FFKM mixtures

FFKM O-rings are used in many different industries. Every industry has its own specific requirements and there are correspondingly many FFKM compounds.

#4 Application range of FFKM O-rings

Aerospace: FFKM O-rings are used in the aerospace industry for engines and other safety-critical components. They must withstand extreme temperatures and harsh environments while meeting the strict regulations of the aerospace industry. One example is our NH5751 HT compound, which has been specially developed for these requirements and can withstand temperatures of up to 330 °C and a variety of harsh chemical environments.

Chemical industry: In the chemical industry, FFKM O-rings are used to withstand the high temperatures and contact with aggressive chemicals that can occur during the processing of fine and specialty chemicals. The NH product range offers FFKM compounds that can be used in a variety of chemical processing applications, including pumps, valves, paint spraying equipment, mechanical seals, dosing systems and heat exchangers.

Pharmaceutical industry: In the pharmaceutical industry, seals must meet the strictest cleanliness requirements and be resistant to aggressive chemicals in CIP/SIP (Clean- and Sterilization-in-Place) processes. FFKM compounds, such as the black NH5700 or the white NH4700 from ECOLASToffer high resistance to acids, alkalis and hot water as well as broad temperature resistance, making them ideal for the demanding requirements of the pharmaceutical industry.

Power generation: In power generation, FFKM O-rings are used for their pressure, temperature and media resistance in demanding environments, including high-speed electric motors with long duty cycles. For example, the ECOLAST compound NH5750 can be used in a variety of harsh environments and offers excellent chemical and thermal resistance.

Food and beverage industry: Hygiene and safety are crucial in this sector. FFKM O-rings can be used throughout the entire process chain, from preparation and production to packaging, distribution and storage, to meet the high standards in this industry.

#5 Why is the durability of FFKM O-rings so high?

Both the extremely high thermal and chemical resistance are due to the solid chemical structure of FFKM.

Definition of media resistance

The media resistance of a material is measured in terms of its resistance to the effects of a chemical.

Sounds great, but what exactly does that mean?

Every elastomer (rubber) consists of so-called polymer chains. These chains consist of individual molecules. The molecules that make up the chain are decisive for the chemical resistance.

Interestingly, the name of each material tells us roughly what molecules it is made of.

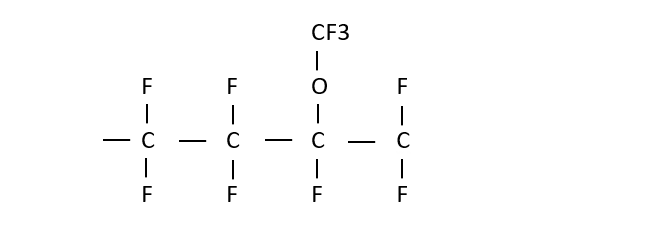

Example FFKM material

The two “F’s” in FFKM stand for fluorine. Fluorine (F) forms an extremely strong bond with the base molecule carbon (C). This bond is so strong that almost no medium has a chance of attacking the FFKM material.

In comparison: FKM (VITON) also consists of carbon and fluorine bonds, but unlike perfluoro rubber, it is not fully saturated. As a result, FKM is significantly more susceptible than FFKM.

For those of you interested in chemistry, here is the structure of the polymer chains:

FFKM polymer chain: Only with strong fluorine bonds

FKM polymer chain: With fluorine and hydrogen bonds

At this point, we could well imagine you asking yourself:

What is FFKM not resistant to?

Care must only be taken with 2 media if FFKM is to be used

1. Media with a high fluorine content (like with like is not compatible)

2. Molten alkali metals (caution: extremely toxic)

Otherwise, you can use FFKM materials almost without hesitation, at least as far as chemical resistance is concerned.

Summary of Chapter 3: FFKM resistance

FFKM is almost universally resistant to media. Due to its solid chemical structure, FFKM is clearly superior to other elastomers such as NBR, EPDM and FKM.

#6 What do I need to consider when designing and installing FFKM O-rings?

Feature | FFKM | FKM |

|---|---|---|

Grouting | 12-18% | 15-25% |

Groove clearance after grouting | 20% | 20% |

Max. Elongation during assembly | <50% | <50% |

Max. Permanent stretching | 3% | 3% |

Max. Permanent compression | 3% | 3% |

Assembly grease | Mineral oil and silicone greases | Mineral oil and silicone greases |

In summary, there are only differences in the desired compression.

This is due to the fact that no swelling is generally assumed with FFKM, as FFKM is almost universally resistant to media. Accordingly, the compression may also be set somewhat lower.

You can also make things very easy for yourself with assembly greases. Just like FKM O-rings, FFKM O-rings are resistant to all oils and greases. You can therefore use any grease or oil during assembly.

Otherwise, as with all elastomers, the 5 basic installation instructions apply

1. no sharp edges

2. use suitable tools

3. clean the groove space thoroughly before installation

4. use suitable assembly grease

5. observe an insertion slope of approx. 20%

Summary Chapter 4: FFKM design and installation

FFKM O-rings are largely designed and fitted in the same way as all other O-rings. Due to its excellent durability, even less attention needs to be paid.

#7 Are there suitable alternatives to FFKM O-rings?

The direct answer: Yes, FEP coated O-rings and pure PTFE O-rings are suitable alternatives to FFKM O-rings to a certain extent.

The advantage of FEP and PTFE O-rings is that they are significantly cheaper than FFKM.

But what are the disadvantages? We can find this out with a brief comparison of the key properties.

FFKM (NH5756 HT) | FEP/SILICON | PTFE |

|---|---|---|

Universally resistant | Universally resistant | Universally resistant |

-15°C to +340°C | -60°C to +205°C | -250°C to +250°C |

Elastic | Partially elastic | Rigid |

Result: In most cases, it only makes sense to replace FFKM O-rings with FEP or PTFE O-rings if media resistance is crucial. This is because O-rings with an FEP jacket or made of pure PTFE are also almost universally resistant to media.

Important: 2 points must be observed during replacement

1. Wf, for example, you want to replace a 20 x 2 FFKM O-ring with an FEP or PTFE material, then the O-ring or, if applicable, the O-ring must be replaced with a new one. the groove must be redesigned. Due to the rigidity and the higher manufacturing tolerances (FEP O-rings), the O-ring cannot simply be replaced 1:1.

2 Despite the rigidity of FEP and PTFE O-rings, installation must be possible. FEP O-rings can only be used as flange and rod seals and PTFE O-rings can even only be used as flange seals.

While FEP O-rings can at least be stretched or compressed a little, this is almost no longer possible with PTFE O-rings.

Side tip: If you place FEP O-rings in hot water at 80°C before fitting, they become slightly more elastic. This also applies to all other elastomers.

Summary Chapter 5: Alternatives to FFKM O-rings

Yes, FEP-coated and pure PTFE O-rings are suitable alternatives to FFKM O-rings, but only if media resistance is the main factor.

#8 Interesting questions: quick and easy answers

Finally, we would like to answer a few questions that we are frequently asked in everyday life.

#8.1 What is the difference between FFKM vs. FFPM O-rings?

There is no difference. FFPM is just an outdated term. Nowadays, perfluoro rubber is abbreviated FFKM in accordance with ISO 3601. Accordingly, both abbreviations stand for the same material: perfluoro rubber.

#8.2 What is the difference between FFKM vs. FKM O-rings?

FKM stands for fluororubber and FFKM for perfluororubber. While FKM has a fluorine content of approx. 60-65%, FFKM has a fluorine content of approx. 70-75%. Accordingly, perfluoro rubber is clearly superior to normal fluoro rubber.

#8.3 What is the difference between FFKM vs. Kalrez O-rings?

FFKM is the material designation and stands for perfluoro rubber. Kalrez, on the other hand, is a trademark for FFKM O-rings from DuPont. While Kalrez was the only FFKM brand many years ago, there are now several new FFKM brands.

ECOLAST = NH O-RING

KALREZ = DuPont

SIMRIZ = Freudenberg

Chemraz = Greene Tweed

#8.4 Why is the price of FFKM O-rings so high?

This is solely due to the price of raw materials. The price per kilogram of FFKM raw material is several thousand euros. This means that FFKM is only used where it is absolutely necessary.

#7.5 How long can FFKM O-rings be stored?

FFKM O-rings have a service life of 13 years.

How long an O-ring may be stored depends on the DIN 7716 . It contains the requirements for optimum elastomer mounting.

#8.6 Up to what minus temperature can FFKM O-rings be used?

Up to what sub-zero temperature FFKM O-rings can be used depends on the specific compound.

The standard compounds (NH5750, NH5700 and NH4700) are resistant between -10°C and -20°C and the compounds (NH5760 LT, NH4702 LT and NH6902 LT) for use in low temperature applications are resistant down to -40°C.

“I am convinced that we should share our knowledge with the world. I hope I have been able to answer all your questions. If you have any further questions, please feel free to contact us at any time. We will be happy to help you.”

Lord of the O-rings

Author of the Sealing Academy