O-RING NOrm ISO 3601 | Design Simply explained

What is ISO 3601?

ISO 3601 is by far the most important O-ring standard at international level. It is divided into five parts and forms the basis for the design and evaluation of an O-ring.

Parts | Content |

|---|---|

ISO 3601-1 | Inner diameter, cord thickness, dimensions and tolerances |

ISO 3601-2 | Installation spaces and general applications |

ISO 3601-3 | Shape and surface applications |

ISO 3601-4 | Selection and types of support rings |

ISO 3601-5 | Requirements for elastomer materials |

#1 What exactly is ISO 3601?

The first version of the international standard ISO 3601 was published back in 1978. This laid the foundation for standardized O-rings in accordance with international standards.

Initially, the first part of the standard only contained the dimensions for O-rings for general use. In this respect, ISO 3601 was strongly based on the now obsolete German standard DIN 3771. At that time, however, the focus was on the inch O-rings, which originate from the American standard AS568.

Only since 2008 has ISO 3601 also reflected the American dimensions. With regard to the desire for an international standard, the American dimensions are converted from inches to millimeters and are also specified as such.

Anglo-American system of measurement: inch (“)

Metric measurement system: millimeters (mm)

Furthermore, 2008 marked a significant step forward in the standardization of O-rings as a sealing element for another reason.

Part 2 of the standard was published this year. This section defines the installation spaces for O-rings in general fluid technology applications. This was the first time that standard sizes with coordinated guide values for the specification of compression and elongation were available.

The tables allow you to work in both directions

1. search for the optimum installation space for a given O-ring dimension

2. search for the optimum O-ring for the given installation space

Part 1 and Part 2 thus bring considerable added value for design engineers all over the world. For a large number of standard applications, the tables provide all the important guide values for designing a high-performance sealing system.

Parts 3 and 5 also make a decisive contribution to this. This is because quality criteria for production and formulation create binding standards.

Summary Chapter 1: Introduction to ISO 3601

ISO 3601 is the most important O-ring standard and the basis for the international standardization of O-rings. Each of its 5 sections defines an important area of O-rings.

#2 How is an O-ring correctly defined? (Part 1)

Basically, an O-ring is fully described by specifying its internal diameter and the cord thickness.

If the combination of inner diameter and cord thickness corresponds to a standardized dimension, there are two major advantages.

The two advantages of standardized dimensions

1. it is likely that the item has a shorter delivery time or is even in stock.

2. the price is often significantly better compared to exceptional dimensions.

Standardized O-ring dimension list | Click here >>

Important: ISO 3601 divides O-rings into two different classes

Class A: O-rings for sensitive applications such as aerospace

Class B: O-rings for standard applications (commercially available O-rings)

Consequently, the main difference between class A and class B O-rings is the tolerance class. In line with the sensitive applications, significantly higher demands are placed on the dimensional accuracy of the O-rings.

Note: If it is not precisely defined, then O-ring tolerance lists always refer to O-rings from class B.

Summary Chapter 2: Definition of an O-ring

An O-ring is described in full with details of the inside diameter and cord thickness. ISO 3601 divides O-rings into class A and B. Commercially available O-rings correspond to class B.

#3 How do I lay out an O-ring optimally? (Part 2)

As we know, the correct design of an O-ring is absolutely crucial for a long-term sealing effect. As a result, the specifications in ISO 3601-2 should always be followed when designing O-rings and installation spaces.

In practice, two cases are important

1. Installation space is given and the appropriate O-ring is sought

2. The O-ring is present and a suitable installation space is sought

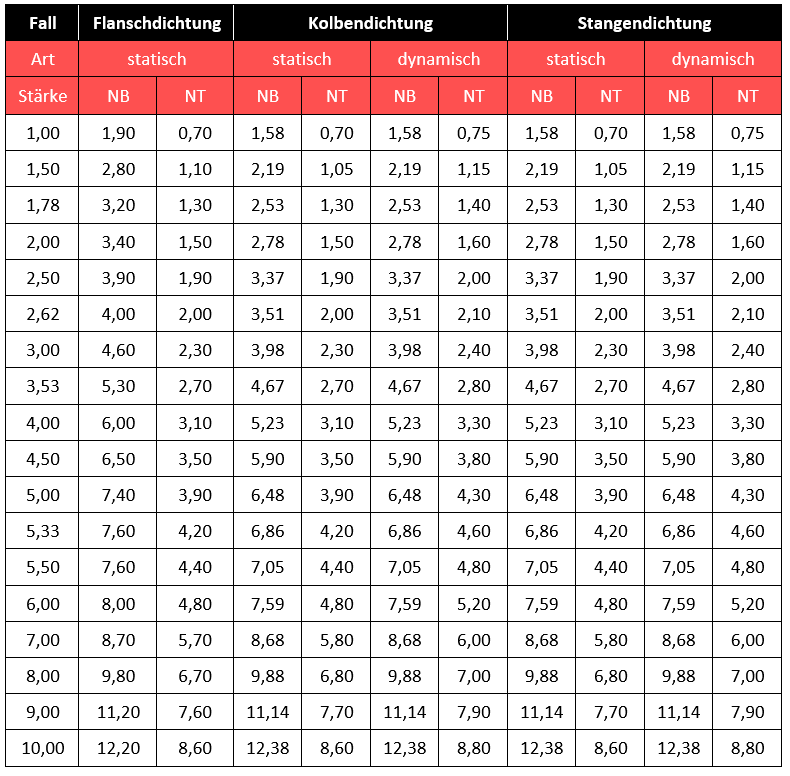

There is a corresponding table for these two cases. This table makes it easy to find the right O-ring or installation space.

The table is divided into 3 applications

1. Flange gasket

2. Piston seal

3. Rod seal

Explanation of the table

All dimensions in mm

Thickness = cord thickness

NB = groove width

NT = groove depth

Static = without movement

Dynamic = with movement

With the help of this table, you can always easily find out which O-ring fits which installation space.

Summary Chapter 3: Design of an O-ring

Using the table from ISO 3601-2, it is easy to see which O-ring is suitable for which installation space. Important: Always consider the application.

#4 What is decisive for the quality of an O-ring? (Part 3)

First and foremost, the manufacturing quality of an O-ring is assessed on the basis of 6 characteristics:

1. Form deviation, offset

2. Indentation

3. Flow lines

4. Burr

5. Deburring area

6. Recesses, indentations

Based on these six characteristics, the permissible deviations are specified in ISO 3601-3. This has created a standard that serves as a basis for the evaluation of an O-ring.

Which surface deviations are permissible depends on the “grade characteristic” of the O-ring. A total of three variety characteristics are distinguished:

The 3 characteristics for O-rings

1. N: Standard quality

2. S: Increased quality requirements

3. CS: Critical applications

Almost all O-rings are manufactured in the standard quality accordingly. If an O-ring is to be manufactured according to the “S” or “CS” grade characteristic, this must always be specified. This is because the more specialized the applications of the O-rings are, the narrower the limits apply to the error sizes.

O-rings with the CS grade feature are primarily reserved for critical applications in the aerospace industry or oxygen equipment. The tolerances can only be achieved with considerable effort in the manufacturing processes.

For example, O-rings with the CS grade feature must not have any measurable indentations. Accordingly, the costs of these O-rings are significantly higher than those of standard qualities.

Summary Chapter 4: Quality of an O-ring

An O-ring can have one of six different surface deviations. In addition, O-rings are classified into three types (N, C, CS).

#5 What types of support rings are there? (Part 4)

Section 4 of the O-ring standard deals with the use of back-up rings .

Depending on the cord diameter from Part 1, Part 4 of the standard assigns back-up rings with specific profile dimensions to the O-rings. They are used to protect O-rings against the effects of excessive pressure.

Important: High pressure and, above all, rapidly changing pressure conditions can lead to mechanical damage to the O-ring.

This allows it to be pressed into the sealing gap on the side facing away from the pressure. Sharp groove edges can shear off parts of the O-ring. Sealing experts also refer to the damage pattern as gap extrusion.

Support rings, which are placed on the side facing away from the pressure, serve as a countermeasure. The hard support ring deforms under load. It closes the sealing gap without sealing it. Instead, it ensures that the O-ring cannot flow in.

Professional tip: Regardless of the printing direction, we recommend always including two support rings. This is because it happens too often that the support ring is fitted on the wrong side (the side facing away from the pressure). However, two support rings must be used for alternating pressure directions.

What types of support rings are there?

T1: Spiral support ring

T2: Diagonally slotted support ring

T3: Unslotted support ring

T4: Diagonally slotted, concave support ring

T5: Unslotted, concave support ring

The selection of the appropriate variant depends primarily on the accessibility of the installation groove and the pressure conditions. Furthermore, it should also be considered whether the seal is stationary or moving.

Note: It makes sense that the groove dimensions in ISO 3601-2 are matched to the dimensions of the back-up rings.

Summary Chapter 5: Back-up rings for O-rings

A support ring supports the stability of an O-ring at high pressures and protects it from gap extrusion. ISO 3601 defines a total of five types (T1-T5) of back-up rings.

#6 What must an elastomer material be able to do? (Part 5)

Media attack, temperatures and pressure: these parameters define highly specific requirements for O-ring materials.

It is not just a matter of selecting a high-performance base elastomer. The formulation must also be selected so that the material properties are ideally suited to the operating conditions.

Whether they do this can be tested with numerous key figures on mechanical properties, temperature and aging behavior.

Since the first version in 2002, ISO 3601-5 has specified requirements for the properties of O-ring materials. However, the standard was initially only suitable as a general selection aid. Depending on the contact media, a suitable elastomer material could be identified.

However, the 2015 edition of brings significant progress. This is because it defines material requirements for common O-ring materials. These include NBR, HNBR, FKM and EPDM.

Particularly important: In addition to the formulation, the production process also influences the properties of the finished part.

Above all, the critical vulcanization step has an effect on the mechanical properties. The specification of the properties of the finished part is therefore crucial.

These characteristic values are used in practice to check a sufficient degree of vulcanization.

If the O-ring conforms to part 5 of the mould, the user is equally protected against gross deviations in the formulation and vulcanization.

Summary Chapter 6: O-ring material requirements

Section 5 of ISO 3601 defines the requirements for O-ring materials. The focus here is particularly on media and temperature resistance.

#7 Interesting questions: quick and easy answers

Finally, we would like to answer a few brief questions on the subject of ISO 3601.

#7.1 Which O-rings fall under ISO 3601-1 Class A?

ISO 3601-1 Class A contains O-rings that are used in sensitive applications. A sensitive requirement is, for example, aviation or a nuclear power plant. In contrast to the standard O-rings on the market (class B), class A O-rings must be within strict tolerances and quality requirements.

#7.2 Which O-rings are covered by ISO 3601-1 Class B?

ISO 3601-1 Class B contains all commercially available O-rings without sensitive application areas. If there is nothing on the label, then O-rings from class B are assumed.

#7.3 What must be written on data sheets according to ISO 3601?

The O-ring standard does not specify any strict requirements for data sheets. However, it has become generally accepted that the following requirements should be stated on data sheets:

The 5 mandatory details for O-ring data sheets

Material specification (ISO designation)

Shore hardness (Shore A or D)

Elongation at break (%)

Tensile strength (MPa)

Compression set (%)

Furthermore also

Tr-10 (°C)

Density (g/cm³)

Tear resistance (N/mm)

#7.4 What other dimensional standards are there in addition to ISO 3601?

ISO 3601 – International Standard – Inch and metric dimensions

DIN 3771 – German standard – superseded by ISO 3601 since 2010

AS568 – American Standard – Inch dimensions

BS 1806 – British Standard – Inch dimensions

BS 4518 – British Standard – Metric dimensions

SMS 1586 – Swedish standard – Metric dimensions

NFT 47-501 – French standard – Metric dimensionsJ

IS B 2401– Japanese standard – Metric dimensions

“I am convinced that we should share our knowledge with the world. I hope I have been able to answer all your questions. If you have any further questions, please feel free to contact us at any time. We will be happy to help you.”

Lord of the O-rings

Author of the sealing academy