Piston seal

Piston seal: Everything you need to know

Piston seals, an indispensable element in many mechanical and industrial systems, ensure the efficient and safe functioning of cylinders and pistons.

In this chapter, we look at what a piston seal is, its basic meaning, and take a brief look at its historical development.

History and development of piston seals

The history of piston seals is closely linked to the development of industrial machinery.

Originally made from simple materials such as leather, piston seals have evolved over time to include a variety of materials and designs tailored to specific applications.

Important milestones:

- Early developments: Introduction of leather seals in early steam engines.

- 20th century: Introduction of synthetic materials such as rubber and plastics.

- Modern times: Development of highly specialized seals for extreme conditions.

The importance of piston seals in the industry

Piston seals are critical to the performance and safety of hydraulic and pneumatic systems.

They prevent the leakage of liquids and gases and thus contribute to the efficiency and durability of the systems. They are used in a wide range of applications, from the automotive and aviation industries to medical technology and power generation.

Application examples:

- Automotive industry: used in brake and suspension systems.

- Aerospace: Important component in engines and control systems.

- Medical technology: used in precision instruments for surgical procedures.

REQUEST O-RINGS QUICKLY AND EASILY?

Almost any dimension available

Offer received in record time

No minimum order quantities or minimum item values

One contact for all concerns

#1 Basics of the piston seal

Piston seals are an essential component of many machines and systems and play a decisive role in the efficiency and safety of hydraulic and pneumatic systems.

At the core of their function, they prevent the escape of fluids or gases and thus ensure the correct operation of pistons in cylinders.

History and development of piston seals

The history of piston seals is a history of progress and innovation. Originally made from simple materials such as leather or woven fabrics, they have evolved considerably with the development of new materials and technologies.

- Early developments (18th and 19th centuries): The use of leather seals in early steam engines marks the beginning of modern piston seal technology.

- Development of rubber and plastic (20th century): With the introduction of rubber and later plastics, piston seals underwent a revolution that dramatically expanded their range of applications.

- Modern materials and designs (21st century): Today, piston seals are made from a variety of advanced materials, including PTFE, NBR and silicone, which are customized for specific applications.

The importance of piston seals in the industry

Piston seals are of central importance for a wide range of industrial applications. Their ability to prevent leaks and minimize friction makes them indispensable for the functionality of machines in various industries.

Industry-specific applications:

- Automotive industry: Here they are crucial for the reliability of braking and steering systems.

- Aerospace: In this sector, they ensure the safety and efficiency of aircraft and spacecraft.

- Mechanical engineering and manufacturing: They are essential for the smooth functioning of production lines and automation systems.

- Medical technology: In high-precision medical devices, they ensure accurate and reliable results.

The development and optimization of piston seals remains a dynamic field, characterized by technological progress and the constant search for more efficient and durable solutions.

#2 Different types of piston seals

The world of piston seals is diverse, with each type specifically designed for certain applications and operating conditions. The main types include:

- Rod seals: Specially designed to prevent the passage of fluid along the moving rod.

- Piston rod seals: These seals work effectively in both the push and pull directions and are crucial for double-acting cylinders.

- Scraper: Prevents impurities from entering the cylinder.

- Guide elements: They minimize the metal contact between piston and cylinder.

Material selection for optimum performance

The choice of material is crucial for the performance and service life of a piston seal. The most common materials include

- Nitrile rubber (NBR): Often used because of its good abrasion resistance and low price.

- Polyurethane (PU): Known for its excellent wear resistance and high pressure resistance.

- Polytetrafluoroethylene (PTFE): Valued for its exceptional chemical resistance and low friction.

- Ethylene propylene diene rubber (EPDM): Ideal for applications that require good heat, water and steam resistance.

Comparison of piston seal materials

Each material has its own specific properties that make it suitable for certain applications. Here is a comparison.

| Material | Advantages | Disadvantages | Field of application |

|---|---|---|---|

| NBR | Good abrasion resistance, cost-effective | Limited chemical resistance | General industry |

| PU | High wear resistance, pressure resistant | Sensitive to high temperatures | High pressure applications |

| PTFE | Low friction, resistant to chemicals | Less elastic, more expensive | Chemical industry |

| EPDM | Excellent heat resistance | Not oil resistant | HVAC systems, water treatment |

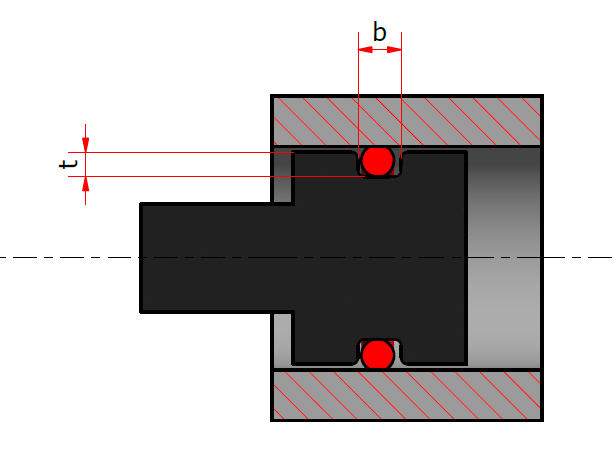

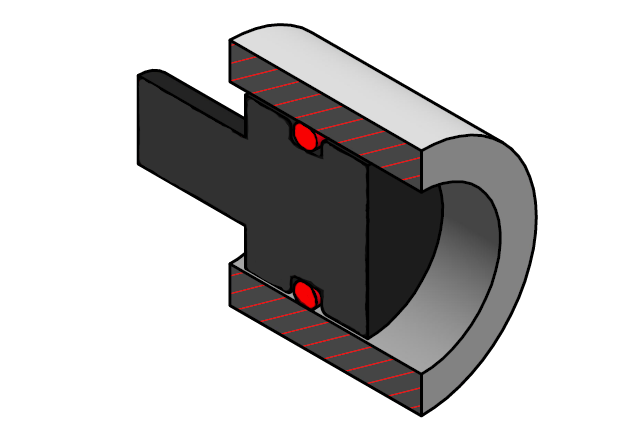

#3 Design aspects of the piston seal

The design of piston seals is crucial to their effectiveness and service life. Important design aspects include:

- Size and fit: Exact dimensions are essential to prevent leaks. Gaskets that are too tight can cause excessive friction, while gaskets that are too loose can cause leaks.

- Sealing lips: The design of the sealing lips significantly influences the sealing performance, particularly in relation to the pressure and speed with which the seal is confronted.

- Grooves and channels: These are important for lubrication and heat dissipation and help to reduce wear and friction.

How does a piston seal work?

Piston seals work by creating a barrier that prevents fluids from escaping. The way they work depends on their type and positioning in the cylinder:

- Rod seals: Seal the space between the moving rod and the cylinder to prevent fluid leakage.

- Piston rod seals: Ensure fluid stays on one side of the piston to allow controlled movement.

- Wipers: Keep out impurities that could damage the seal.

Customization of the design for specific requirements

Customization of piston seals to meet specific requirements is essential for performance. Some customizations include:

- High temperature applications: Use of heat-resistant materials such as PTFE or silicone.

- Chemical resistance: Use of materials such as Viton or PTFE, which are inert to a wide range of chemicals.

- High pressure: Reinforced design and more robust materials to withstand the load.

A well thought-out design and the right choice of materials are essential to ensure the efficiency and durability of piston seals in their respective applications.

#4 Guide to the installation of piston seals

The installation of piston seals is a precise process that requires careful planning and execution to ensure optimum performance and longevity of the system.

Here are some practical tips for the successful installation of piston seals:

Thorough preparation:

- Make sure that all surfaces on which the seal is to be mounted are clean, smooth and free of dirt or burrs.

- Check the dimensions of the seal and the installation surface to ensure that they match.

Tools and materials:

- Use suitable tools for installation to avoid damaging the seal.

- If necessary, use a lubricant that is compatible with the sealing material and the medium to be sealed.

Correct assembly:

- Take care not to overstretch or deform the seal.

- Follow the manufacturer’s instructions regarding the alignment and positioning of the seal.

Prevention of tilting and twisting:

- Make sure that the seal sits evenly and is not twisted or tilted. This could otherwise lead to leaks or premature failure.

- Make sure that the seal sits evenly and is not twisted or tilted. This could otherwise lead to leaks or premature failure.

Careful commissioning:

- After installation, it is advisable to commission the system slowly and carefully at first in order to run in the seal and detect any faults at an early stage.

- After installation, it is advisable to commission the system slowly and carefully at first in order to run in the seal and detect any faults at an early stage.

Regular review:

- Check the seal regularly for signs of wear or damage and replace it if necessary.

- Check the seal regularly for signs of wear or damage and replace it if necessary.

Consideration of the operating conditions:

- Observe the specific operating conditions such as pressure, temperature and the medium being sealed. Make sure that the seal is suitable for these conditions.

By following these steps, you can extend the life of your piston seal and improve the efficiency and reliability of your system. Correct installation is crucial to avoid problems such as leaks and failures.

#5 The future of piston seal technology

The future of piston seal technology is characterized by innovations and further developments aimed at increasing efficiency, durability and environmental compatibility.

This chapter provides an outlook on trends and technological developments in the world of piston seals.

Innovative developments in sealing technology

Research and development in the field of piston seals is increasingly focusing on the following aspects:

- Improved materials: The development of new materials that are more resistant to abrasion, high temperatures and chemical influences.

- Intelligent sealing systems: Introduction of sensor technologies in seals to monitor condition and performance in real time.

- Sustainable solutions: Focus on more environmentally friendly materials and production processes.

Sustainability and environmental impact

Sustainability is becoming increasingly important in the industry, and piston seals are no exception. Future developments include:

- Reduction of the ecological footprint: use of recyclable or bio-based materials.

- Energy efficiency: Development of seals that generate less friction and thus enable energy savings.

- Durability: Longer seal life reduces the need for frequent replacement and waste.

These developments show that the piston seal industry is not only making technological progress, but is also increasingly taking responsibility for the environment and sustainability.

#6 FAQ section: Piston seal

Finally, some answers to frequently asked questions.

#6.1 What are the main functions of piston seals?

Piston seals are crucial for preventing the escape of liquids and gases in hydraulic and pneumatic systems.

They ensure the required tightness and enable efficient and low-friction movement of the pistons in cylinders.

Their main functions include maintaining pressure, preventing contamination and minimizing friction losses, which increases the overall performance and reliability of the system.

#6.2 What materials are used for piston seals?

Piston seals are made from a variety of materials, including nitrile rubber (NBR), polytetrafluoroethylene (PTFE), polyurethane (PU) and ethylene propylene diene rubber (EPDM).

The choice of material depends on the specific application and takes into account factors such as temperature resistance, chemical resistance, pressure ranges and abrasion resistance. Each material offers unique properties that make it suitable for specific operating conditions.

#6.3 In which applications are piston seals used?

Piston seals are widely used in various industries, including automotive, mechanical engineering, aerospace and medical technology.

In the automotive industry, they are used in braking and steering systems, while in mechanical engineering they are indispensable for the functionality of production systems.

In the aerospace industry, they ensure the safety of critical systems, while in medical technology they are crucial for the precision of medical devices.

#6.4 How does the choice of material affect piston seals?

The choice of material has a significant influence on the performance of piston seals. It determines the resistance to various operating conditions such as temperature, pressure and chemical substances.

For example, PTFE offers excellent chemical and temperature resistance, while NBR is known for its abrasion resistance and cost-effectiveness. The right choice of material ensures a longer seal life and improved reliability of the entire system.

#6.5 Why is the correct installation of piston seals important?

Correct installation is crucial for the performance and longevity of piston seals.

Improper installation can lead to leakage, increased friction and premature wear. It is important to install the seals in accordance with the manufacturer’s instructions, to ensure the correct size and alignment and, if necessary, to carry out appropriate lubrication.

Professional installation helps to reduce downtime and maximize the efficiency of the system.

#6.6 What trends are emerging in the development of piston seals?

Future trends in piston seal technology will focus on the development of more sustainable materials, the integration of sensor technologies and the improvement of performance.

Innovative materials offer improved resistance to abrasion and extreme conditions. Sensors in seals enable real-time condition monitoring, which improves maintenance and efficiency.

We are also working on more environmentally friendly solutions that reduce the ecological footprint and contribute to sustainability in the industry.

“I am convinced that we should share our knowledge with the world. I hope I have been able to answer all your questions. If you have any further questions, please feel free to contact us at any time. We will be happy to help you.”

Lord of the O-rings

Author of the Sealing Academy