10 questions: O-ring data sheets

In this short article, we answer the 10 most important questions about the correct design of O-ring data sheets in a simple and understandable way.

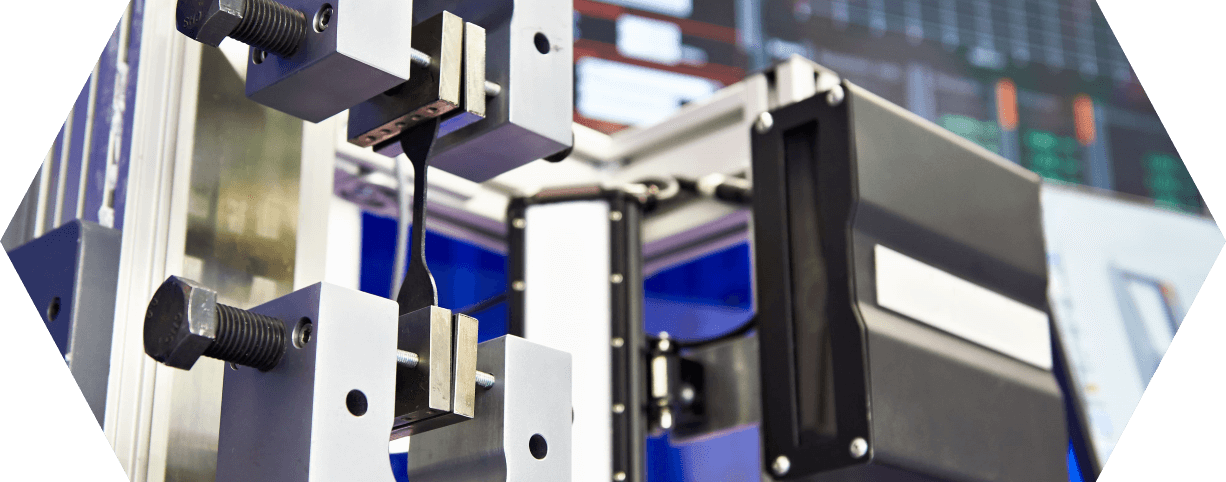

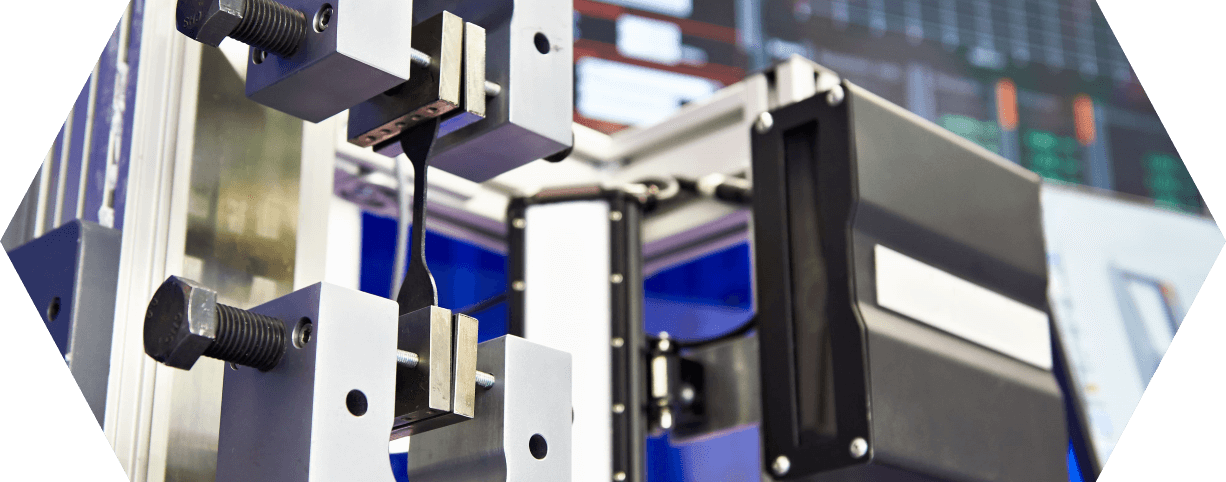

O-rings made of elastomers must function in use without exception. By closing the sealing gap, they separate two areas in a system or device from each other.

This prevents components from being attacked by aggressive media, for example. They also protect sensitive substances from unwanted and potentially dangerous contamination by other substances. To achieve this, the O-rings must be able to withstand numerous loads.

Careful selection of the O-ring, its conscientious manufacture and professional installation are essential conditions for this. Experts around the world are constantly working on the further development of O-ring materials, manufacturing processes and the design of installation spaces.

However, another decisive factor often remains in the background: the conditions under which O-rings are stored. Under optimum storage conditions, O-rings retain their sealing properties for years. However, errors during storage can cause the O-rings to age in fast motion. Here you can find out what

storage of elastomers.

Damage analysis plays an important role in the successful use of O-rings as a sealing element. If an O-ring fails, users should take the time to examine the component. The reason for the loss of the sealing effect can often be identified.

Damage patterns include brittleness of the material, cracking or permanent deformation. All this means that the O-ring can no longer reliably close a sealing gap, which itself is also subject to changes due to operating conditions.

However, it is not always easy to draw conclusions about the underlying damage mechanisms. Particularly under harsh operating conditions, several harmful factors often work together. Experts differentiate between these causes of damage:

But why is this relevant for the storage of your O-rings? Because the life of elastomer O-rings begins with vulcanization. This is where the components are given their cohesion and elastic properties. Experienced manufacturers use their special know-how.

This is because optimum vulcanization determines the performance of the O-rings. At the same time, the process requires a precise interaction of time, pressure and temperature. Manufacturing defects play a subordinate role with high-quality O-rings.

What is much more important is that from the vulcanization stage onwards, harmful environmental influences can cause deviations.

from the target state.

Depending on the duration of storage, the O-rings in the bearing may be exposed to unfavorable conditions for more or less time. To ensure that the O-rings are still in the desired condition when they are installed, you should therefore pay particular attention to creating optimum conditions in the bearing.

Dhe formulations of many elastomer materials contain stabilizers to prevent damage, but anti-ageing agents and protective layers against ozone or UV light attack are also used. Because they can only slow down ageing, but not stop it, good storage is essential.

You should ensure optimum storage conditions, especially for longer storage periods of more than six months. Particularly sensitive elastomers for special applications can even be damaged much earlier.

In tests, O-rings made of the elastomer NBR show the first cracks after just a few days in ozone-containing air. PTFE O-rings also illustrate how critical correct storage is: the material has outstanding media resistance and, thanks to its wide temperature range, is suitable for

suitable for many sealing applications.

But the material tends to cold flow. Even a slight pressure load can lead to permanent deformation. Manufacturers can counteract this by using suitable recipe ingredients. Nevertheless, PTFE O-rings should be carefully stored to protect them from the effects of pressure. DIN 7716 provides general guidelines on how to store elastomer products. The standard classifies elastomers on the basis of their formulation and specifies maximum storage times.

Base elastomer / Maximum storage time

This shows: With proper storage, users of elastomer O-rings can use them even after a long period of time without any loss of function. However, this only applies if the bearings also meet the high demands placed on the sealing elements. Generally

The requirement is for a cool, dry, low-dust storage location protected from excessive air exchange. The detailed requirements of DIN 7716 for the storage room can be classified into these categories:

Protect your stock of O-rings from direct sunlight. UV radiation in particular damages the elastomers. However, excessive local heating also causes the O-rings to age more quickly.

It is best to keep the O-rings in closed boxes for as long as possible. They shield the sealing elements from daylight. Film bags made of UV-resistant polyethylene (PE) provide good protection.

The relative humidity in the storage room should not exceed 70 percent. Maximum values of 65 percent come even closer to the ideal. The O-rings should reliably protect you from contact with condensation. Some elastomers are more susceptible than others.

The individual elastomer types also differ in detail with regard to the target temperatures for storage. The target range is marked by a minimum temperature of +5 degrees and a maximum temperature of +25 degrees. When cold, the O-rings can become very stiff.

They should therefore be given some time to warm up at room temperature before installation. This makes installation easier and protects against damage. Heat sources installed in the storage room should not be able to radiate heat directly onto the O-rings. This is ensured by a minimum distance of one meter or suitable shielding.

Airtight containers or PE bags protect elastomer O-rings from the effects of harmful media from the ambient air. At the same time, there should be no excessive air exchange in the storage room. Elastomers absorb oxygen on their own.

They bind part of it and release the rest back into the environment in a modified form as oxidation products. This ageing reaction severely impairs the mechanical properties of the O-ring. The same applies to ozone.

Fluorescent tubes, electric motors and many other electrical devices produce gas during operation. O-rings made of the elastomer NBR in particular are very quickly damaged by ozone-containing air.

Mechanical stress during storage can also cause irreversible damage to the O-ring before it is even installed at the place of use. Ideally, the components should therefore be in a relaxed state during the storage period.

Neither pressure nor tension act on the sealing elements. Pressure marks are often caused by staples or other objects, especially when O-rings are stored in a distributed manner. In the case of O-rings with large diameters, however, relaxed mounting can be a challenge.

To keep the space requirement within limits, O-rings with an internal diameter of over 300 millimeters can be hammered in.

However, kinks must be avoided at all costs. There are also other important notes in connection with the storage of elastomers. Contact with heavy metals such as manganese, copper or iron can also cause O-rings to age. This should be avoided, as should storage together with PVC. After prolonged storage, it may be necessary to clean the O-ring.

Warm water and a clean cloth should be used. Under no circumstances should cleaning fluids such as benzine, benzene or turpentine be used. You should keep O-rings away from pointed or sharp objects, not just when cleaning them, but whenever you handle them.

With the right storage, you can easily keep O-ring stocks locally. This means you can react to a failure at any time. You do not have to worry about any loss in the function of the O-rings from our own warehouse. The development of systematic warehousing offers many advantages.

The central storage of O-rings allows the reduction of distributed stocks. This reduces the quantity held in stock. This also ensures that the oldest O-rings are always used first. The packaging units can also remain closed for longer.

The storage system also prevents mix-ups. We at NH Dichtungsservice support you with storage. We supply our O-rings optimally protected in individual packaging units and apply markings according to customer requirements. This ensures the necessary safety and efficiency when using O-rings.

“I am convinced that we should share our knowledge with the world. I hope I have been able to answer all your questions. If you have any further questions, please feel free to contact us at any time. We will be happy to help you.”

Lord of the O-rings

Author of the sealing academy

In this short article, we answer the 10 most important questions about the correct design of O-ring data sheets in a simple and understandable way.

In this short article, we answer the 10 most important questions about the correct design of O-ring grooves in a simple and understandable way.

In this short article, we answer the 10 most important questions about the correct storage of O-rings in a simple and understandable way.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information