O-ring groove calculation made easy

Did you know that almost all O-ring failures are due to incorrectly designed grooves? With our tool, you can avoid exactly that.

Our calculation tool is suitable for the following materials:

FFKM (ECOLAST), FKM, NBR, HNBR, EPDM, SILIKON, FVMQ, FEPM, CR and ACM.

Important notes:

- PTFE and FEP coated O-rings should only be used as flange gaskets.

- PTFE O-rings have their own table values and therefore also a separate groove calculation. If you need support with the design of PTFE O-rings, please do not hesitate to contact us.

Our tool for calculating an O-ring groove is based on the values in the ISO 3601 table.

There are basically two starting points:

- You know your O-ring and are looking for the right groove.

-> Fill in the “Cord thickness” field and our tool will calculate the optimum groove for you. - You know your groove and are looking for the right O-ring.

-> Fill in the groove width/groove depth field and our tool will calculate the optimum O-ring cord thickness for you.

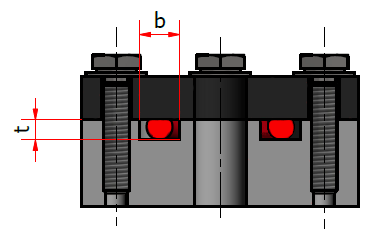

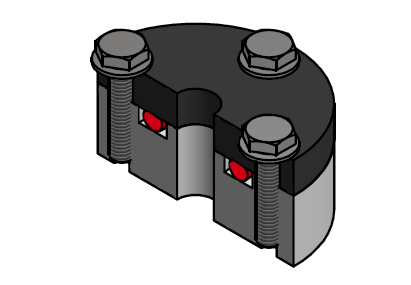

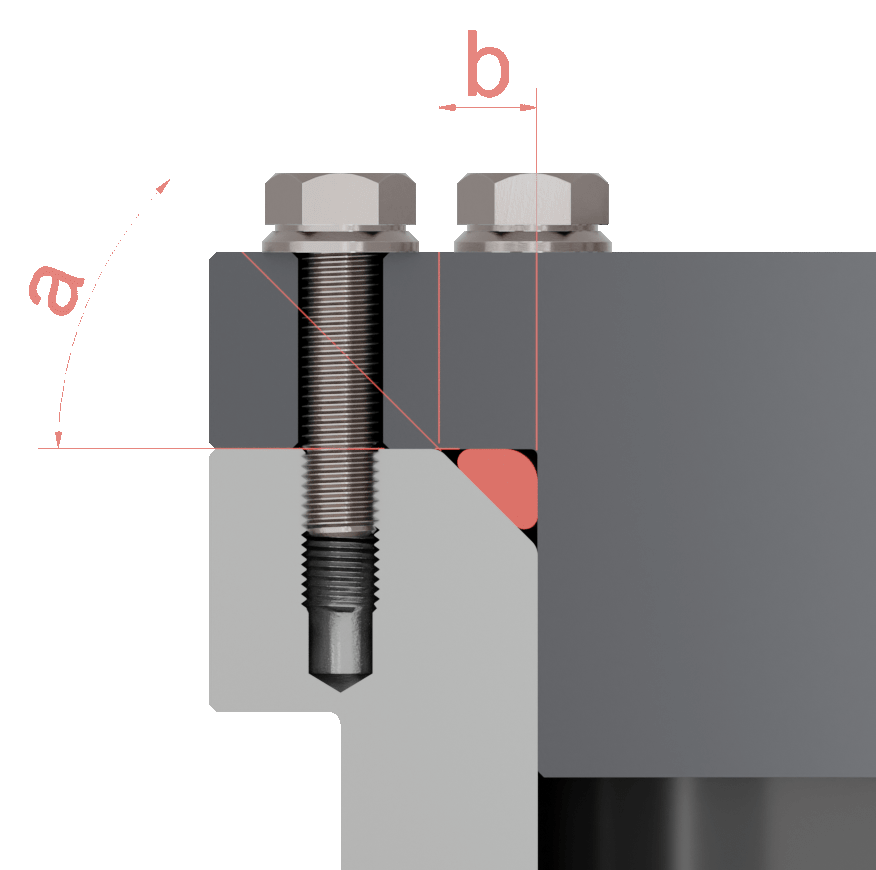

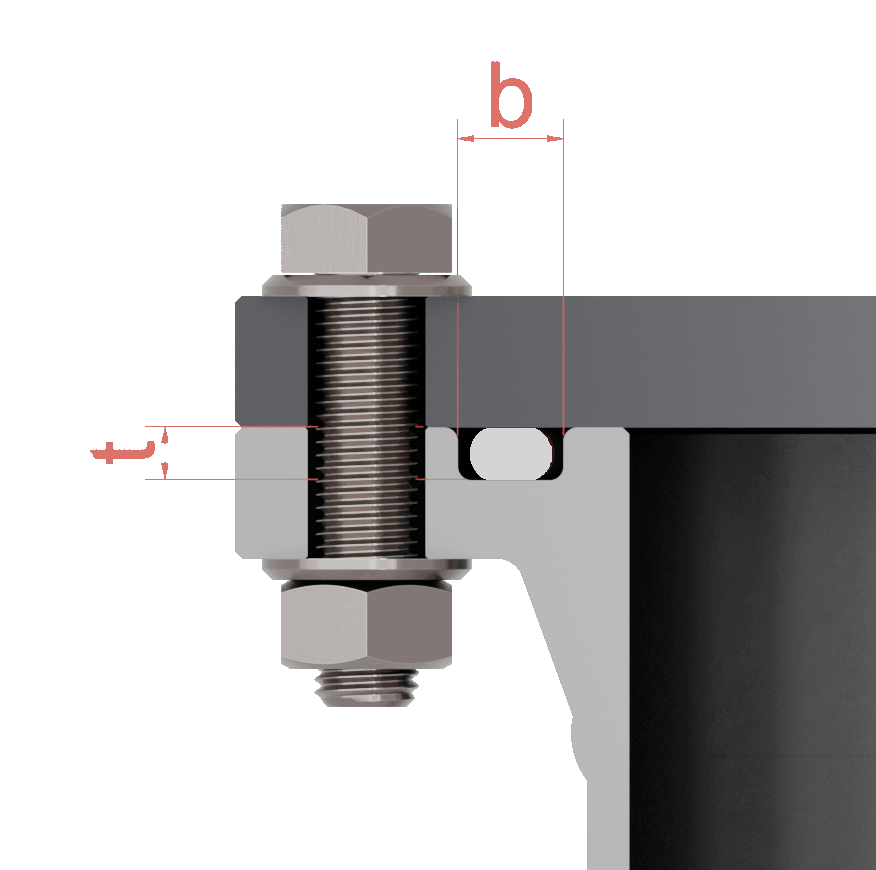

Definition of a flange gasket:

Flange gaskets are pressed axially by screwing a cover rigidly to the flange. With continuous connections between two pipes, two flanges can also be tightly joined together. Flange gaskets are non-moving (static) gaskets.

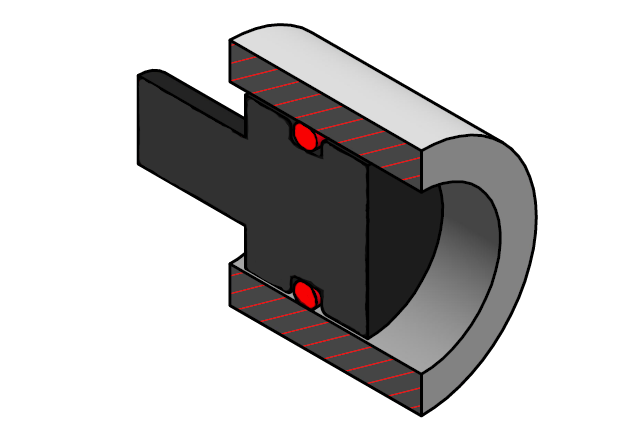

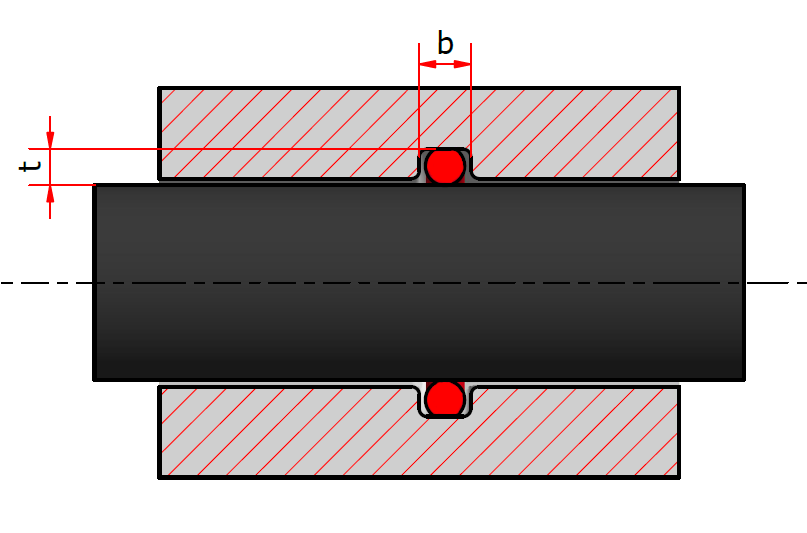

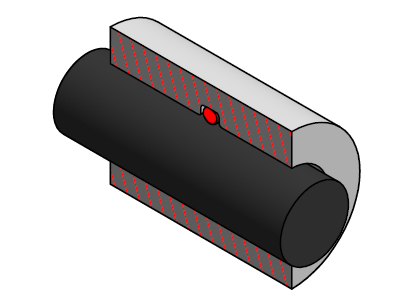

Definition of a piston seal:

The groove is located in the inner part of a piston, for example, and the O-ring inside is pressed radially (pressing line is at 90° to the axis).

Piston seals are very common in hydraulic cylinders, for example. Accordingly, the majority of piston seals are used as dynamic seals.

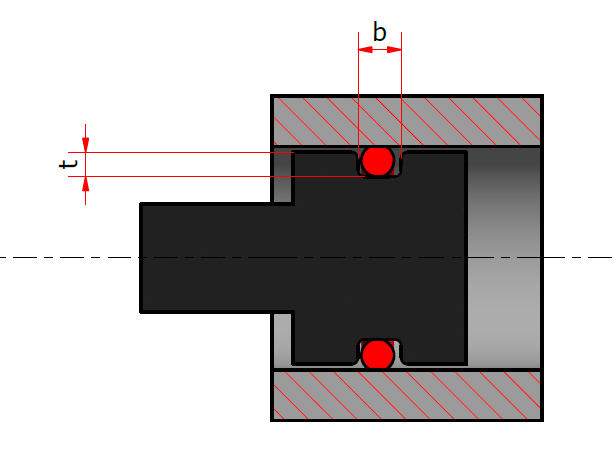

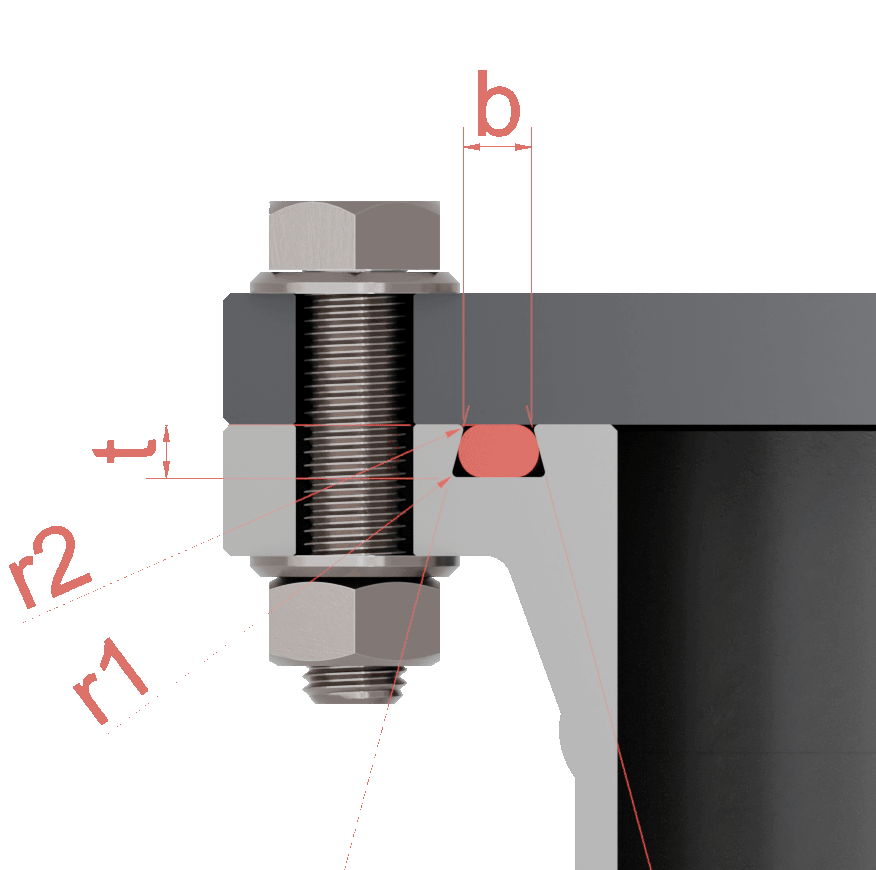

Definition of a rod seal:

Rod seals are sealing elements that separate components from each other in an axial direction. They are pressed in a radial direction and are mainly used in moving (dynamic) seals. Depending on the installation position, they have an internal or external sealing effect.

All values are given in millimeters [mm].

Static sealing = no movement

Dynamic sealing = movement

We reserve the right to make errors and changes. The values given are not binding and are merely recommendations. If you have any further questions, please contact us at “info@nh-oring.de”.