O-RINGS MEssen | Design Simply explained

Everything you need to know about O-ring assembly

Mechanical damage is the most significant cause of failure for O-rings.

Designers can do a lot to ensure the durability of the seal during the design phase. However, this only controls part of the mechanical failure risk.

What remains is the assembly as an uncertainty factor.

The seal can only function reliably in the long term if the initial installation of the O-ring is carried out just as carefully as all regular replacement processes. And there are a few things to bear in mind.

REQUEST O-RINGS QUICKLY AND EASILY?

Almost any dimension available

Offer received in record time

No minimum order quantities or minimum item values

One contact for all concerns

#1 O-ring assembly: This is what matters

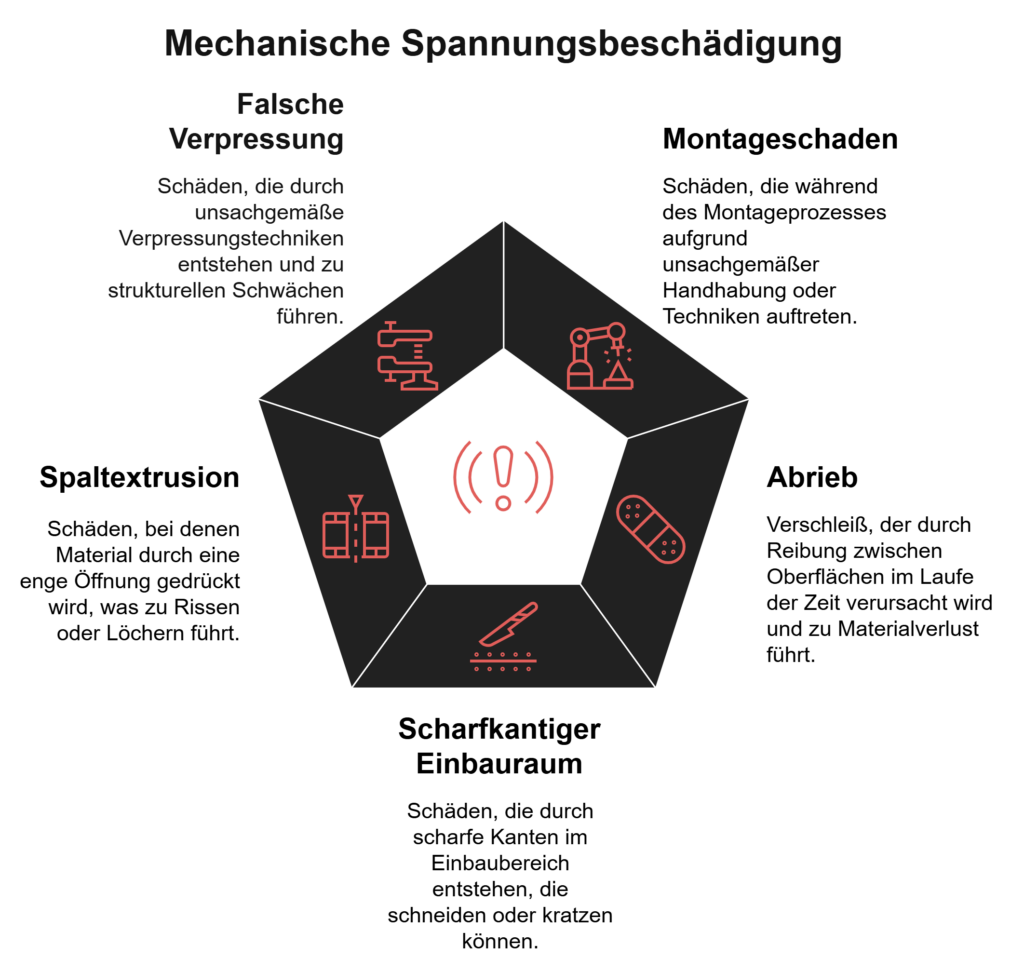

Assembly-related damage is one of many types of damage that can lead to premature failure of an O-ring.

They fall into the category of damage caused by mechanical stress:

- Assembly damage

- Abrasion

- Sharp-edged installation space

- Gap extrusion

- Incorrect pressing

If the sealing element is permanently mechanically damaged during installation, this can reduce its durability to a fraction of the expected service life – resulting in high costs and unstable operation.

For this reason, assembly and maintenance personnel must take particular care when fitting O-rings.

O-rings require a minimum amount of compression between the sealing surfaces in order to reliably separate the two areas even if changing operating conditions or external influences change the sealing point.

Accordingly, the O-ring must be deformed during assembly. If this happens in an uncontrolled manner, considerable damage can occur.

- Twisting

In many installation situations, O-rings are compressed on the inside diameter. It can therefore be difficult to insert the O-ring into the installation groove of a piston seal, for example. Assembly greases and oils are suitable for reducing friction during the assembly process. Nevertheless, the friction can cause the O-ring to twist excessively. This creates cracks that weaken the material bond. - Overstretching

When installing an O-ring in a piston seal, stretching serves to reduce friction until the O-ring slides into its final position. As a general rule, 50 percent of the specified elongation at break applies as a permissible measure for installation-related elongation. With less elastic materials, however, the limit value for unproblematic elongation can be significantly lower. As with twisting, overstretching also causes cracks to form on the O-ring. Appropriate installation aids or automatic installation can significantly reduce the risk of damage. - Crushing

After the O-ring is seated in its mounting position in a piston seal, the piston rod must be inserted into the cylinder. If the workpieces are not positioned exactly in relation to each other, the O-ring may be crushed. A hard edge of the workpiece presses into a part of the O-ring. This means that the nominal dimension of the grouting is no longer guaranteed over the entire circumference. Loose particles can also lead to more friction or contamination. Assembly devices are used as aids to ensure that the workpieces are correctly aligned with each other.

Assembly-related damage is indicated by a very short service life of the O-ring. To avoid this, the special features of different types of sealing must be taken into account during installation in addition to the general specifications.

#2 O-ring assembly and the different sealing types

Depending on the accessibility and orientation of the installation groove, different procedures are required during installation. Assembly personnel should be made aware of the respective points of error and use suitable assembly aids.

Flange seals are characterized by very good axial accessibility of the installation space.

Hardly any stretching is required for installation. Nevertheless, attention is required during installation. With the flange gasket, there is a particularly high risk that the cover will not initially fit correctly during installation, leading to crushing of the O-ring.

Piston seal

Just like the rod seal, the piston seal consists of an O-ring with a radial installation direction.

The installation groove of the piston seal is located in the inner part (piston). The O-ring must be stretched in order to insert it into the groove.

An expanding sleeve is used to create the necessary expansion without causing permanent damage to the O-ring. In addition, a sufficiently long guide must be provided when the piston with the O-ring is inserted into the cylinder.

This ensures correct positioning of the two workpieces and prevents crushing of the O-ring.

Rod seal

With the rod seal, the installation space for the O-ring is located in the outer part (cylinder). The assembly personnel must deform the O-ring to bring it into its final position.

For assembly, the O-ring should be pressed together into a kidney-like shape. Once the installation space is reached, the O-ring snaps into place. If the seals are sufficiently elastic, manual compression of the O-rings is not a problem.

Less flexible O-rings should be brought into the kidney shape using an assembly aid. These ensure that the O-rings are not bent too much locally.

#3 Optimum assembly for the various groove shapes

When designing the installation space, designers can make use of different groove shapes. They deviate from the standard case – the rectangular groove – if technical reasons require this at a specific point.

Only special cases justify the use of complex and therefore more expensive groove shapes.

Rectangular groove

The rectangular groove is the predominant installation space for the use of piston, rod and flange seals.

As a basic prerequisite for installation, all groove edges must be provided with sufficient radii. This also includes clean surfaces and sufficient insertion bevels.

In pressurized applications, there is also a special feature: the O-ring must be in contact with the side of the groove facing away from the pressure in order to prevent it from moving.

Trapezoidal groove

The trapezoidal groove (also known as a dovetail groove) is shaped in such a way that the groove holds the O-ring in a defined position.

This not only simplifies the assembly process, but also maintenance. This can also be useful during operation, for example if machines or tools regularly open and close at the sealing point.

The upper edge of the groove must be provided with a sufficiently large radius so that the O-ring is not damaged during installation. The same applies to the half trapezoidal groove, where only one flank of the groove holds the O-ring.

Triangular groove

A triangular groove is an alternative for the design of flange seals. In this case, the O-ring is in contact with three contact surfaces when pressed. The sealing function is heavily dependent on the precise design of the groove.

During installation, particular care must be taken to ensure that the O-ring is positioned correctly and is not crushed by the cover.

#4 Observe material properties during design

During installation, it is not only the type of seal and the groove shape that determine the correct procedure.

The special properties of the respective gasket material must also be taken into account. While most O-ring materials are elastic, there are also materials that are only reversibly deformable to a very limited extent.

This applies above all to O-rings made of PTFE. Stretching, compressing or buckling must be avoided at all costs. FEP O-rings are somewhat less critical than the rigid PTFE O-rings. Nevertheless, their installation requires special care.

They consist of a rubber core encased in plastic. If the protective sheath is overstretched during installation, cracks will occur. As a result, the more vulnerable core is exposed to the media attack.

#5 Observe material properties during design

Lubricants are a key aid in making assembly easier.

They reduce friction and can therefore make the installation of O-rings more efficient and safer. They also extend service life by permanently reducing friction in dynamic applications.

When selecting a lubricant, media compatibility should be the main deciding factor. VMQ O-rings, for example, are made of silicone and are attacked by silicone-based lubricants.

In contrast, NBR O-rings benefit from a silicone-based lubricant due to improved protection against the effects of weathering. Mineral oil-based lubricants are an alternative to silicone.

However, pairing with EPDM, which is not resistant to mineral oil, must be avoided at all costs.

#6 Conclusion on O-ring assembly

Assembly plays a key role in preventing premature damage to the O-ring.

On the one hand, the installation process serves to check the preparation of the installation space. Installation may only be carried out if the processing of the groove complies with the specifications.

On the other hand, the installation itself should be carried out using suitable tools and with great care in order to achieve a satisfactory service life.

“I am convinced that we should share our knowledge with the world. I hope I have been able to answer all your questions. If you have any further questions, please feel free to contact us at any time. We will be happy to help you.”

Lord of the O-rings

Author of the Sealing Academy