Piston seal

#1 What is a piston seal?

O-rings can be installed in three different ways.

1. Flange gasket

2. Piston seal

3. Rod seal

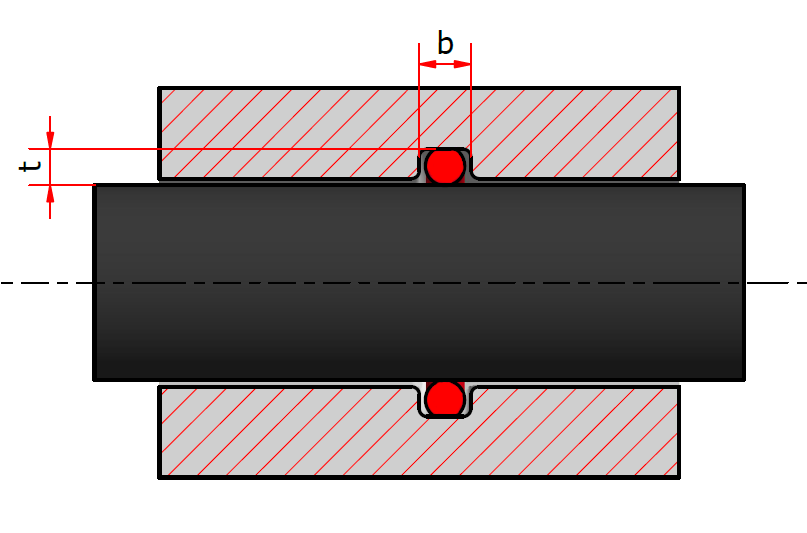

Definition of a piston seal: The groove is located in the inner part of a piston, for example, and the O-ring inside is pressed radially (pressing line is at 90° to the axis).

In addition to the type of installation, a distinction is also made between static and dynamic applications.

Static = Without movement

Dynamic: With movement

Piston seals are very common in hydraulic cylinders, for example. Accordingly, the majority of piston seals are used as dynamic seals.

#2 What must be observed with a piston seal?

It is important to know that the groove space must be designed differently for the piston seal than is the case with the more common flange seal.

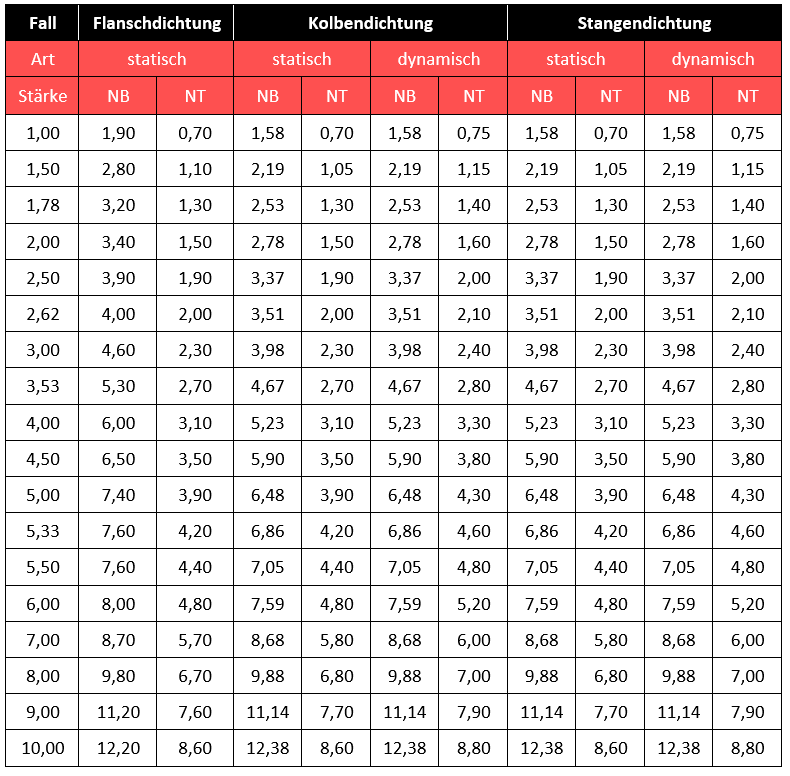

The following table corresponds to the specifications of ISO 3601 section 2 and provides information on which O-ring is suitable for which installation space (groove).

Legend to the table

All dimensions in mm

Thickness = cord thickness

NB = groove width

NT = groove depth

static = without movement

dynamic = with movement

Two things can be deduced from the table on closer inspection:

1. The groove width is slightly smaller for piston and rod seals. Accordingly, the O-ring is left a little less space in the groove.

2. The groove depth and thus the grouting is the same for all three static sealing cases. However, in a dynamic application, the groove is designed to be slightly deeper. This is because the compression should tend to be lower with a moving seal.