ELASTOMER

Elastomer: Everything you need to know

Elastomers, often perceived as ordinary rubber, are in fact a cornerstone of modern engineering and design.

These remarkable materials, known for their elasticity and resilience, have quietly woven themselves into the fabric of our daily lives.

From the tires that mobilize our vehicles to the seals that protect our machines, elastomers play a central role in a variety of industries.

In this comprehensive guide, we will delve into the world of elastomers and explore their nature, their diversity and the science that drives them.

We strive to shed light on their diverse applications, the complex processes behind their manufacture and the technological innovations that drive their development.

Our journey through this fascinating subject will be informative, enriched with facts, lists and tables for a deeper understanding, and written in a simple, accessible style.

Whether you are a student, an industry professional or simply curious about the materials that shape our world, this article promises to provide you with valuable insights into the diverse world of elastomers.

Let’s start by unraveling the basics: What exactly are elastomers?

| Fact | Fact Description | Meaning |

|---|---|---|

| Discovery | Natural rubber was first used by indigenous peoples of South America. | Shows the long history and cultural significance of elastomers. |

| Vulcanization | Developed by Charles Goodyear in 1839, vulcanization improves the heat resistance and strength of rubber. | A turning point in the use of elastomers, which led to their widespread use in industry and everyday life. |

| Synthetic elastomers | Developed in the early 1900s in response to increasing demand and limited natural sources. | Enabled customized elastomers for specific applications and revolutionized many industries. |

| Self-healing elastomers | Modern research is developing elastomers that can repair damage themselves. | This innovation could significantly improve the longevity and sustainability of elastomer products. |

| Bio-based elastomers | Current research is focused on the development of elastomers made from renewable raw materials. | An important step towards reducing the environmental impact and promoting sustainable materials. |

| Global production | Global production of synthetic rubber exceeded that of natural rubber for the first time in 2014. | This shows the growing demand and importance of synthetic elastomers in the global economy. |

REQUEST O-RINGS QUICKLY AND EASILY?

Almost any dimension available

Offer received in record time

No minimum order quantities or minimum item values

One contact for all concerns

#1 What are elastomers? - A comprehensive introduction

Elastomers are fascinating materials that are characterized by their extraordinary ability to return to their original shape after being deformed.

This property makes them an indispensable component in many applications, from the automotive industry to medical technology.

The definition of elastomers

Elastomers, often referred to simply as “rubber”, are polymers with the unique ability to expand when stretched or compressed and then return to their original shape.

This property, known as elasticity, distinguishes elastomers from other materials such as plastics or metals.

Types of elastomers

There are two main categories of elastomers: natural and synthetic. Natural elastomers, such as latex, are obtained from the sap of certain plants.

Synthetic elastomers, such as neoprene or silicone, on the other hand, are produced chemically and often offer improved properties for specific applications.

| Type of elastomer | Type of elastomer Description | Typical application |

|---|---|---|

| Natural rubber (latex) | Obtained from plant sap | Tires, tubes |

| Neoprene | Synthetic, oil-resistant | Diving equipment, seals |

| Silicone | Heat-resistant, flexible | Cooking utensils, medical devices |

#2 The science behind elastomers

Elastomers are not only interesting because of their practical applications, but also because of the fascinating science behind their unique properties.

In this section, we will take a closer look at the composition and function of elastomers.

Composition and properties of elastomers

Elastomers consist of long polymer chains that can be deformed under tension or pressure and then return to their original shape.

This flexibility is due to the chemical structure: The polymer chains are cross-linked, which allows them to stretch and contract again.

- Chemical structure: Elastomers consist of polymers with a flexible, cross-linked structure.

- Physical properties: They are known for their high elasticity, resistance to environmental influences and damping properties.

How elastomers work

When an elastomer is stretched, the polymer chains expand. After the force is removed, these chains return to their original position.

This property enables elastomers to be used in a variety of applications where flexibility and resistance are required.

- Behavior under stress: Elastomers can stretch to a certain extent without being damaged.

- Recovery after deformation: After relief, they return to their original shape.

Environmental factors and their effects

The properties of elastomers can be influenced by various environmental factors. Temperature, chemicals and UV radiation can affect elasticity and durability.

- Temperature: Extreme cold or heat can affect elasticity.

- Chemical influences: Some chemicals can attack and weaken elastomers.

- UV radiation: Long-term exposure to UV radiation can lead to embrittlement.

#3 Applications of elastomers in everyday life

Elastomers can be found in numerous everyday objects and industries due to their versatile properties.

This section highlights some of the most important applications of elastomers and how they influence our everyday lives.

Elastomers in the automotive industry

Elastomers are indispensable in the automotive industry. They are used in a wide range of components, from tires to seals and hoses.

- Tires: Elastomers ensure the flexibility and durability of car tires.

- Seals and hoses: They provide an important sealing function to prevent the ingress of liquids and gases.

Medical use of elastomers

Elastomers play a crucial role in medicine, especially in the manufacture of flexible and safe medical devices.

- Prostheses: Elastomers provide flexibility and comfort for artificial limbs.

- Medical devices: They are used in tubes, seals and even surgical instruments.

Elastomers in consumer products

Many household products are also made of elastomers. From kitchen appliances to sports equipment, they contribute to durability and functionality.

- Kitchen utensils: Heat-resistant handles and flexible shapes.

- Sports equipment: comfort and cushioning in shoe soles and protective equipment.

#4 Production and processing of elastomers

The process of manufacturing and processing elastomers is crucial to their quality and performance. In this section, we look at the various steps and techniques involved in the production of elastomers.

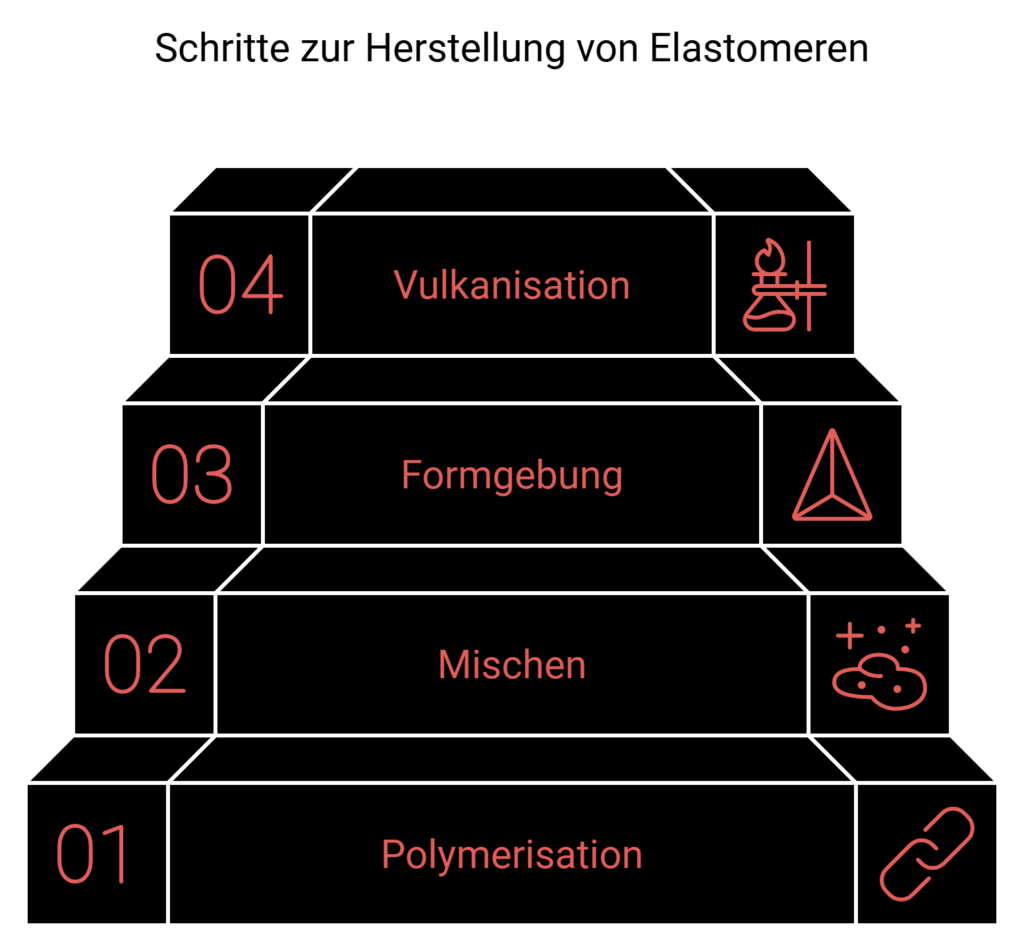

The elastomer production process

The production of elastomers involves several phases, starting with polymerization, followed by mixing, moulding and finally vulcanization.

- Polymerization: The first step in which small molecules (monomers) are combined to form long polymer chains.

- Mixing: Additives and fillers are added here to achieve the desired properties of the elastomer.

- Shaping: The elastomer compound is shaped into the desired form, for example by extrusion or pressing.

- Vulcanization: A critical step in which chemical bonds are formed between polymer chains by heating to improve elasticity and strength.

Quality assurance and test procedures

Quality control is an integral part of elastomer production. Various tests are carried out to ensure that the elastomers meet the required specifications.

- Tensile strength tests: Testing of strength and elasticity.

- Ageing tests: Evaluation of durability under different environmental conditions.

- Chemical resistance tests: Determination of resistance to chemicals and solvents.

#5 Technological advances in elastomer research

Research and development in the field of elastomers has led to significant technological breakthroughs.

These advances not only expand the application possibilities of elastomers, but also contribute to more sustainable production.

The latest innovations in elastomer technology

Continuous research has led to new elastomer types and improved properties. The most notable developments include:

- Self-healing elastomers: These can regenerate their structure independently after damage.

- Thermoplastic elastomers: They combine the processing properties of plastics with the elasticity of rubber.

- Bio-based elastomers: Development of more environmentally friendly, biodegradable elastomers.

Sustainable practices in elastomer production

In response to environmental concerns, sustainable practices are increasingly being implemented in the elastomer industry:

- Recycling of elastomers: Methods for the recycling and reuse of elastomers.

- Reduction of emissions and waste: implementation of more environmentally friendly production processes.

Table: Milestones in elastomer research

| Year | Innovation | Significance |

|---|---|---|

| 2000 | Development of self-healing elastomers | Revolutionizing longevity |

| 2010 | Introduction of thermoplastic elastomers | Expands the processing possibilities |

| 2020 | Emergence of bio-based elastomers | Promotes more environmentally friendly alternatives |

#6 Challenges and solutions in the elastomer industry

Despite their diverse applications and technological advances, elastomers face a number of challenges, particularly with regard to environmental aspects and performance under extreme conditions.

Common challenges when using elastomers

Some of the most common problems in the use of elastomers include:

- Environmental impact: The production and disposal of elastomers can be harmful to the environment.

- Durability under extreme conditions: Elastomers can fail under extreme temperatures or in contact with certain chemicals.

Overcoming these challenges

The industry is continuously working on solutions to overcome these challenges:

- Development of more environmentally friendly elastomers: research into biodegradable and recyclable elastomers.

- Improving resistance: Development of elastomers that are more resistant to extreme temperatures and chemicals.

Case study: Sustainable elastomer production

A recent case study illustrates how a leading company in the elastomer industry has transformed its production to minimize its environmental impact.

By introducing recycling methods and developing biodegradable elastomers, the company has been able to significantly reduce its ecological footprint.

- Main results: Reduction of waste, lower energy consumption and improved sustainability.

- Long-term benefits: These changes not only contributed to environmental protection, but also improved the company’s public image and led to cost savings.

#7 Conclusion on the elastomer

The world of elastomers is wide-ranging and impressive.

From a deep understanding of their chemical and physical properties to their diverse applications in industry and everyday life, we have seen how elastomers play a key role in our modern world.

- Summary of the importance of elastomers: Elastomers are indispensable for many industries and have a significant impact on our everyday lives.

- Looking to the future: With advancing technological developments and a growing focus on sustainability, elastomers are on the cusp of even more innovative applications and more environmentally friendly production methods.

Elastomers symbolize man’s remarkable ability to create and manipulate materials that not only meet our needs, but also help to improve the quality of our lives.

Ongoing research and development in this area promises exciting new breakthroughs and applications that will further enrich both our industry and our daily lives.

#8 FAQ section: Elastomer

Finally, some answers to frequently asked questions.

#8.1 What are elastomers and where are they used?

Elastomers are polymeric materials that are characterized by their high elasticity and flexibility. They can stretch under load and return to their original shape once the load has been removed.

Elastomers are used in a wide range of applications, including in the automotive industry for tires and seals, in medical technology for prostheses and hoses, and in household products such as kitchen utensils and sports equipment.

#8.2 What is the difference between natural and synthetic elastomer?

Natural elastomers, such as latex, are obtained from the sap of certain plants. They are biodegradable, but often less resistant to environmental influences than synthetic variants.

Synthetic elastomers, such as neoprene or silicone, are chemically manufactured and offer improved properties such as oil and heat resistance, which are required for specific industrial applications.

#8.3 How do environmental factors influence the properties of elastomers?

Environmental factors such as temperature, chemicals and UV radiation can significantly influence the properties of elastomers.

Extreme temperatures can change their elasticity and strength, while certain chemicals can attack the material structure. UV radiation can lead to embrittlement and color changes. Therefore, choosing the right elastomer for specific environmental conditions is crucial.

#8.4 How do technological advances contribute to the development of new elastomer types?

Technological advances in material science have led to the development of new elastomer types that address specific challenges.

Examples include self-healing elastomers that can repair damage on their own, thermoplastic elastomers that are easier to process and more environmentally friendly, bio-based elastomers. These innovations expand the application possibilities of elastomers and contribute to sustainability.

“I am convinced that we should share our knowledge with the world. I hope I have been able to answer all your questions. If you have any further questions, please feel free to contact us at any time. We will be happy to help you.”

Lord of the O-rings

Author of the Sealing Academy