Thermoplastic elastomer

Thermoplastic elastomer: Everything you need to know

Thermoplastic elastomers (TPE) have become an indispensable material in today’s world. They combine the advantages of plastic and rubber, making them suitable for use in a wide range of industries. In this article, we take a comprehensive look at TPEs – from their definition and production to their applications and future prospects.

Thermoplastic elastomers are known for their flexibility, durability and ability to maintain their properties at different temperatures. The versatility of this material makes it a preferred choice for engineers and product designers in various industries.

In the following sections, we will go into detail about the different aspects of TPE to give you a deep understanding of this fascinating material. Whether you are an expert in the field of material science or simply want to learn more about TPE, this article will provide you with valuable insights and information.

Comparison of thermoplastic elastomers and other polymers

| Material type | Physical properties | Typical applications |

|---|---|---|

| Thermoplastic elastomers (TPE) | Flexible, elastic, can be processed thermoplastically, good weather resistance | Seals, medical devices, automotive parts, toys |

| Polypropylene (PP) | High rigidity, good chemical resistance, low density | Packaging, automotive components, textiles, household appliances |

| Polyethylene (PE) | Soft, high toughness, chemical resistance, low water absorption | Bottles, pipes, films, toys |

| Polystyrene (PS) | Stiff, brittle, good dimensional stability, clear or colored | Disposable tableware, packaging, housings for electronics |

| Polyvinyl chloride (PVC) | Rigid or flexible variants, good chemical and flame resistance | Pipes, hoses, floor coverings, cable sheathing |

| Natural rubber | High elasticity, abrasion resistance, good tensile strength | Tires, rubber bands, shoe soles, hoses |

REQUEST O-RINGS QUICKLY AND EASILY?

Almost any dimension available

Offer received in record time

No minimum order quantities or minimum item values

One contact for all concerns

#1 What are thermoplastic elastomers?

Definition and basics of TPE

Thermoplastic elastomers (TPE) are a class of polymers that combine the properties of elastomers and thermoplastics.

Elastomers are materials that are highly elastic and can return to their original shape after being stretched. Thermoplastics, on the other hand, are plastics that become malleable when heated and retain their shape when cooled.

TPEs combine these two properties by being both elastic at room temperature and malleable at higher temperatures.

The chemistry behind TPE

At a molecular level, TPEs consist of blocks of hard and soft segments. The hard segments (often made of crystalline polymers) give the material strength and dimensional stability, while the soft segments (often made of amorphous polymer) provide elasticity.

By combining these segments in different ratios, manufacturers can produce TPEs with specific properties that are suitable for certain applications.

Example of the chemical composition of TPE:

- Hard segments: polypropylene (PP), polyethylene (PE)

- Soft segments: ethylene-propylene-diene monomer (EPDM), styrene block copolymers (SBC)

This composition makes TPEs an extremely versatile material that offers both the processability of plastics and the flexibility of rubber.

#2 Manufacturing process of thermoplastic elastomers

The production of thermoplastic elastomers is a complex process that requires precision and expertise. Here is a simplified overview of the essential steps:

Selection of raw materials: Production begins with the selection of the right polymers, which form both the hard and soft segments.

Mixing the polymers: The selected polymers are mixed in a high-temperature process, which distributes the hard and soft segments on a molecular level.

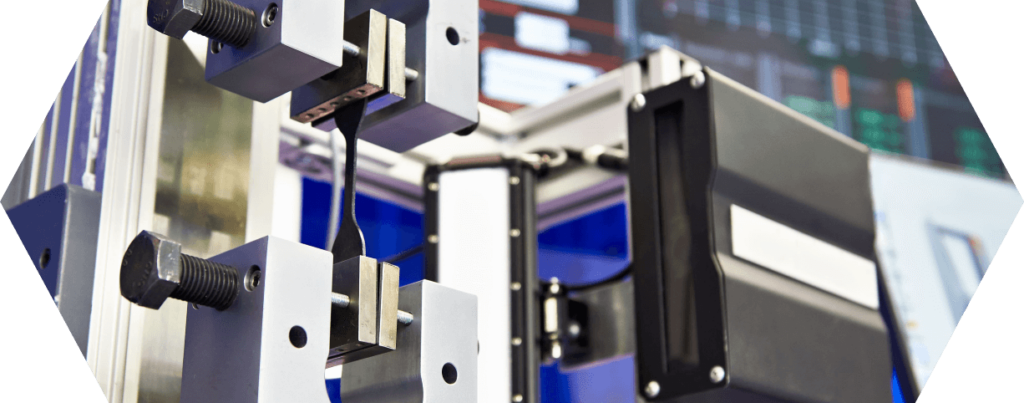

Extrusion: The molten TPE material is pressed through a die to give it the desired shape. This can be a film, a pipe, a profile or another product.

Cooling and curing: After shaping, the material is cooled, which causes it to harden and take on its final shape.

Post-processing: In some cases, the TPE material is further processed, e.g. by cutting, embossing or coating, in order to achieve the final product properties.

Quality control and standards

Quality control is a crucial part of the TPE manufacturing process. This includes:

- Testing the material properties: Tests to determine the strength, elasticity and temperature resistance of the TPE.

- Compliance with industry standards: Ensuring that the TPE produced meets international standards such as ISO and ASTM.

- Consistency tests: Ensuring that each batch of TPE produced has consistent properties.

Compliance with these quality standards ensures that the finished TPE product meets customer expectations and the requirements of the respective application.

#3 Applications of thermoplastic elastomers

TPE in the industry

Thermoplastic elastomers are widely used in various industries due to their unique properties. Some of the most notable applications are

- Automotive industry: used for seals, hoses, damping elements, and in interior components due to its durability and resistance to temperature fluctuations.

- Medical technology: production of catheters, medical tubes and flexible containers, as TPEs are biocompatible and can be sterilized.

- Building industry: Used in window and door frame seals as well as in insulation materials due to its weather resistance and thermal properties.

TPE in everyday products

In addition to industrial use, TPEs can also be found in many everyday products:

- Household appliances: handles and knobs on kitchen appliances, as TPEs offer a pleasant feel and are heat-resistant at the same time.

- Sports equipment: grip tapes for rackets and bikes that provide slip resistance and comfort.

- Toys: Soft, flexible parts in toys that are safe and durable.

The versatility of TPEs allows them to be used in a wide range of applications, making them an invaluable material in modern product development.

#4 Properties and advantages of TPE

Thermoplastic elastomers offer a unique combination of properties that set them apart from other materials:

- Flexibility and elasticity: TPEs can be stretched and deformed and still return to their original shape.

- Thermoplastic processability: In contrast to conventional rubber, TPEs can be deformed when heated and hardened when cooled, which simplifies production.

- Resistance to chemicals and weathering: TPEs are resistant to many chemicals and environmental influences, which increases their longevity.

- Excellent colorability: TPEs are easy to color, which is an advantage for the aesthetics of products.

Ecological aspects of TPE

TPEs also have ecological advantages:

- Recyclability: TPEs can be recycled and reused, which reduces the environmental impact.

- Energy efficiency in production: The manufacturing process for TPE consumes less energy compared to other materials.

- Reduction of waste: Since TPEs can be produced in precise shapes and sizes, material waste is reduced.

This combination of technical and ecological advantages makes TPE a preferred material in many industries, especially in areas where sustainability and environmental friendliness play an important role.

#5 Future prospects and innovations at TPE

Research and development in the field of thermoplastic elastomers is dynamic and future-oriented. Some of the current focal points are

- Improving material properties: Researchers are working on TPEs with higher temperature and chemical resistance in order to expand their areas of application.

- Development of sustainable TPEs: Efforts are being made to produce TPEs based on biodegradable or renewable raw materials in order to minimize the environmental impact.

- Integration in intelligent systems: TPEs are being researched in smart technologies, such as wearables and sensor technology, to enable new functionalities.

Challenges and opportunities

Despite their many advantages, thermoplastic elastomers face certain challenges:

- Recycling and reuse: The development of more efficient recycling methods for TPE remains a challenge in order to further reduce the ecological footprint.

- Costs and manufacturing processes: Optimizing production costs and processes is crucial to making TPEs accessible to a wider range of applications.

Nevertheless, the future of TPEs looks promising. As research and development progresses, TPEs can play an even greater role in various industries by providing innovative solutions to technical challenges while contributing to sustainability.

#6 Conclusion on thermoplastic elastomers

Thermoplastic elastomers represent a fascinating fusion of plastic and rubber properties that make them indispensable in modern materials technology.

From their unique flexibility and moldability to their adaptability in various industrial and everyday applications, TPEs offer exceptional versatility.

The ongoing innovations and research in the field of TPEs promise an exciting future in which these materials will play a role not only in their traditional areas of application, but also in new, revolutionary technologies.

The development of more environmentally friendly and sustainable TPE variants in particular is becoming increasingly important in an increasingly environmentally conscious world.

Despite some challenges in terms of recycling and production costs, the potential of thermoplastic elastomers remains enormous.

With their ability to constantly evolve and adapt to new requirements, TPEs will undoubtedly continue to play a key role in materials science and engineering.

#7 Short questions about thermoplastic elastomers

In the following chapter we will answer further questions on the subject of tensile strength and tensile testing.

#7.1 What are the main advantages of thermoplastic elastomers compared to conventional materials?

Thermoplastic elastomers offer a unique combination of flexibility and thermoplastic processability.

Compared to conventional materials such as rubber or plastics, they are easier to shape and process, offer greater elasticity and are more resistant to environmental influences and chemicals. These properties make them ideal for a wide range of applications in the automotive industry, medical technology and many other sectors.

#7.2 Can thermoplastic elastomers be recycled?

Yes, thermoplastic elastomers can be recycled. Unlike cross-linked elastomers, which cannot be melted and reused, TPEs can be reheated and reshaped.

This makes them a more environmentally friendly option as they can help reduce waste and resource consumption.

#7.3 In which industries are thermoplastic elastomers mainly used?

TPEs are widely used in various industries.

The main sectors include the automotive industry (for seals, hoses and interior components), medical technology (for flexible hoses and containers), construction (for seals and insulating materials) and the manufacture of household goods and sports equipment.

| Type of TPE | Properties of TPE | Trade names |

|---|---|---|

| Styrene block copolymers (SBCs) | High elasticity, good UV and weather resistance | Kraton®, Styroflex® |

| Thermoplastic polyolefins (TPOs) | Good impact strength, chemical resistance, recyclable | Engage®, Catalloy® |

| Thermoplastic polyurethanes (TPUs) | High abrasion resistance, oil and solvent resistance, flexibility at low temperatures | Elastollan®, Desmopan® |

| Thermoplastic vulcanizates (TPVs) | Good heat resistance, flexible, very good processability | Santoprene®, Sarlink® |

| Thermoplastic polyester elastomers (TPE-Es or COPEs) | High heat resistance, good chemical resistance, high strength | Hytrel®, Arnitel® |

| Amide-based thermoplastic elastomers (PEBA) | Very high elasticity and strength, low density, good UV resistance | Pebax®, Vestamid® |

#7.4 What makes thermoplastic elastomers particularly suitable for use in medical technology?

TPEs are particularly valuable in medical technology as they are biocompatible and sterilizable. Their flexibility and resistance to body fluids and cleaning agents make them ideal for applications such as catheters, medical tubing and flexible containers.

In addition, they can be formulated so that they do not contain harmful plasticizers or latex, which increases safety for patients.

“I am convinced that we should share our knowledge with the world. I hope I have been able to answer all your questions. If you have any further questions, please feel free to contact us at any time. We will be happy to help you.”

Lord of the O-rings

Author of the Sealing Academy